News & Events

22 2025-03

22 2025-03 40% Bronze powder PTFE rod: new composite materials lead new trends in industrial applications

Recently, a PTFE rod material containing 40% Bronze powder has attracted widespread attention in the industrial field. This new composite material combines the excellent conductivity of copper with the corrosion resistance and high temperature resistance of PTFE materials, bringing innovative solutions to multiple industries.

11 2022-10

11 2022-10 What are the six types of valve flange gaskets?

Graphite Gasket

Flat gasket made of soft graphite, suitable for high temperature and strong corrosive media.

Metal gasket

There are three main types:

1. Octagonal and oval pads - suitable for trapezoidal groove flange sealing surfaces.

2. The tooth form is a bevel-shaped corrugation machined on the sealing surface of the metal flat gasket - suitable for the concave-convex flange sealing surface.

3. The lens gasket is suitable for the sealing surface of the lens flange, and the metal gasket is made of pure iron, extremely mild steel, stainless steel, aluminum and other materials.

26 2022-09

26 2022-09 What are the main products of rubber gaskets?

The main products of rubber gaskets on the market are: silicone pads, nitrile rubber pads, fluororubber pads, and other rubber pads. Silicone rubber has outstanding resistance to up and down temperature, maintains good application elasticity in the temperature range of -70℃~+260℃, is resistant to ozone and weathering, and is suitable for sealing gaskets in thermal machinery.

17 2022-09

17 2022-09 Graphite composite gaskets are corrosion resistant

Graphite composite gasket, also known as reinforced graphite gasket or high-strength graphite gasket, is a kind of gasket made of sprinted metal tooth plate or metal mesh plate and expanded graphite particles. It is usually stamped or cut from reinforced graphite sheet by gasket cutting equipment. The commonly used inner layer reinforcement materials for reinforced graphite gaskets are S304, S316 or tinplate and other materials.

30 2022-08

30 2022-08 What is the function of installing the octagonal metal ring gasket?

The octagonal metal ring gasket is installed in the trapezoidal ring groove on the flange surface. When the connecting bolt is tightened, it is axially tightened and the upper and lower trapezoidal grooves are tightened, resulting in plastic deformation, forming an annular sealing belt and establishing an initial seal. After boosting under the action of medium pressure, the ring gasket radially expands. The gasket and the inclined surface of the trapezoidal groove are more tightly attached, resulting in a self-tightening effect.

25 2022-08

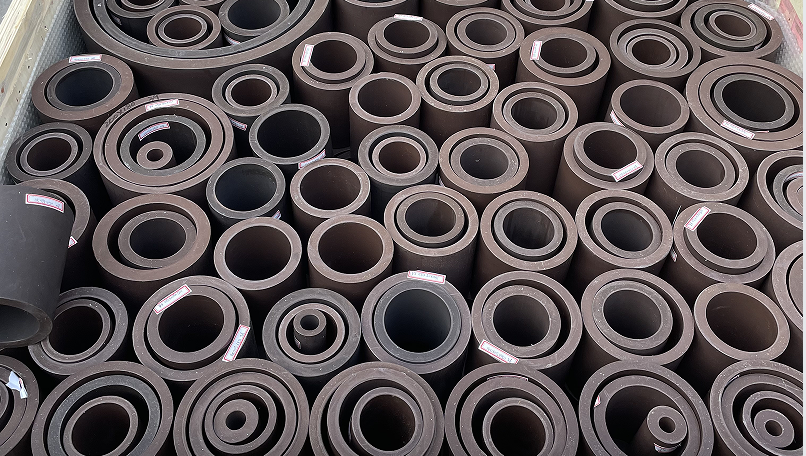

25 2022-08 Spiral wound gasket is an important sealing element

Spiral wound gasket is an important sealing element. Metal spiral wound gasket is widely used in petroleum, chemical, metallurgy, power generation, shipbuilding and other industries. It is the key component of static sealing of pressure pipes, valves, pumps, heat exchangers and other equipment. part. Therefore, the selection and use of high-quality spiral wound gasket products is of great significance to reduce and eliminate running, running, dripping and leaking, and to ensure the safety of the host equipment and the normal operation of the pressure pipeline.