Ceramic Fiber

What is Ceramic Fiber?

Ceramic fiber is a lightweight, high-temperature insulation material composed primarily of alumina-silica. It is manufactured through a melting and blowing or spinning process, resulting in a flexible, fibrous product. This material is known for its exceptional thermal stability, low thermal conductivity, and resistance to thermal shock, making it ideal for various industrial applications where high temperatures are involved.

Key Product Parameters

Our ceramic fiber products are engineered to meet rigorous industrial standards. Below are the detailed parameters that define their performance and quality.

Physical and Thermal Properties

- Composition: Typically 40-60% Al₂O₃, 40-60% SiO₂, with minor additives for enhanced properties.

- Temperature Range: Continuous use up to 1260°C (2300°F), depending on the grade.

- Thermal Conductivity: Low values, e.g., 0.09 W/m·K at 500°C, ensuring efficient insulation.

- Density: Ranges from 64 kg/m³ to 192 kg/m³, offering flexibility in application weight.

- Tensile Strength: High resistance to tearing and abrasion, suitable for demanding environments.

- Chemical Stability: Resistant to most acids and alkalis, except hydrofluoric acid and strong alkalis.

Product Forms and Specifications

Ceramic fiber is available in multiple forms to suit different industrial needs. The table below summarizes common types and their key attributes.

| Product Form | Thickness (mm) | Density (kg/m³) | Max Temperature (°C) | Common Applications |

|---|---|---|---|---|

| Blanket | 12.5 - 50 | 64 - 128 | 1260 | Furnace linings, expansion joints |

| Module | 150 - 300 | 128 - 192 | 1430 | High-temperature kilns, reactors |

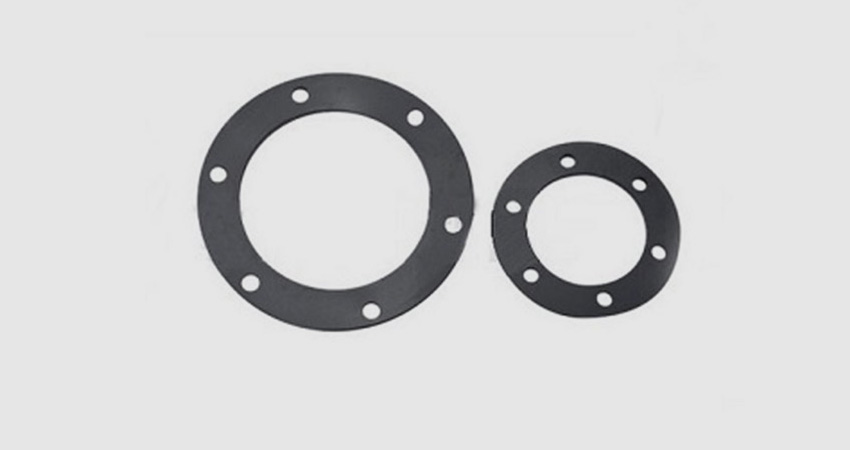

| Paper | 1 - 5 | 180 - 220 | 1260 | Gaskets, wrapping insulation |

| Board | 6 - 50 | 250 - 320 | 1260 | Industrial ovens, fire protection |

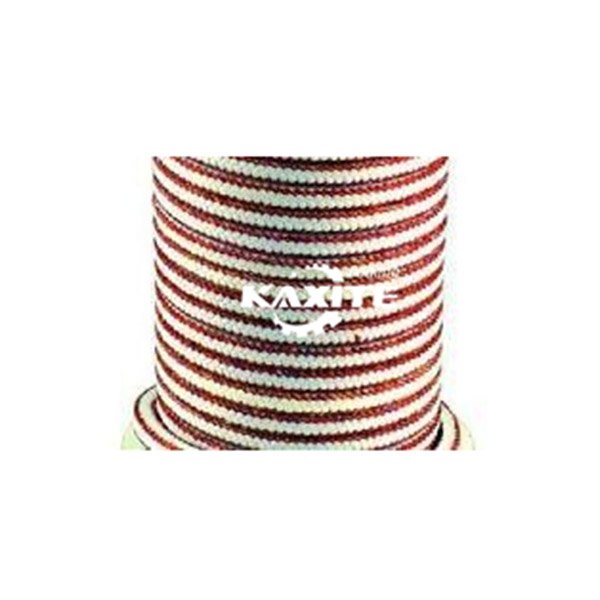

| Yarn and Rope | Diameter 3-20 mm | Varies | 1260 | Sealing, packing materials |

Advantages of Ceramic Fiber

- High Thermal Efficiency: Reduces energy consumption by minimizing heat loss.

- Lightweight: Easier to handle and install compared to traditional refractories.

- Flexibility: Can be shaped and cut to fit complex geometries.

- Low Heat Storage: Allows for rapid heating and cooling cycles, improving process efficiency.

- Durability: Long service life with minimal degradation under high temperatures.

Applications of Ceramic Fiber

Ceramic fiber is widely used across various industries due to its versatile properties. Common applications include:

- Metallurgy: Lining for furnaces, ladles, and tuyeres.

- Petrochemical: Insulation in reformers, crackers, and boilers.

- Power Generation: Protection for turbines, ducts, and exhaust systems.

- Automotive: Heat shields and exhaust insulation.

- Construction: Fireproofing and insulation in buildings.

Ceramic Fiber FAQ

What is the maximum temperature ceramic fiber can withstand?

Ceramic fiber products can withstand continuous temperatures up to 1260°C (2300°F), with some high-purity grades rated for 1430°C (2600°F). The exact maximum temperature depends on the product form and composition.

Is ceramic fiber safe to handle?

While ceramic fiber is generally safe when installed, it can release airborne fibers during handling that may irritate the skin, eyes, and respiratory system. It is recommended to use personal protective equipment (PPE) such as gloves, goggles, and masks during installation. Once in place, the fibers are typically encapsulated and pose minimal risk.

How does ceramic fiber compare to traditional refractory materials?

Ceramic fiber offers advantages such as lower weight, better thermal insulation, and easier installation compared to traditional refractories like firebrick. It also has lower heat storage, allowing for faster thermal cycling. However, it may be less resistant to mechanical abrasion in some applications.

Can ceramic fiber be used in corrosive environments?

Ceramic fiber is resistant to most chemicals, including acids and alkalis, but it is vulnerable to hydrofluoric acid, phosphoric acid, and strong alkalis at high temperatures. For corrosive environments, specialized coatings or higher-purity grades may be recommended.

What is the typical lifespan of ceramic fiber insulation?

The lifespan varies based on operating conditions, such as temperature, mechanical stress, and chemical exposure. Under standard conditions, ceramic fiber can last 5-10 years or more. Regular inspections can help identify signs of degradation, like fiber shrinkage or dusting, indicating the need for replacement.

How is ceramic fiber installed?

Installation methods depend on the product form. Blankets and modules are often secured with anchors or welding pins in industrial settings. Boards can be cut to size and adhered with high-temperature mortars. Proper installation ensures optimal performance and longevity.

Does ceramic fiber contain asbestos?

No, modern ceramic fiber products are asbestos-free. They are made from synthetic materials like alumina-silica and are classified as synthetic vitreous fibers. However, they may still require careful handling to avoid respiratory irritation.

Can ceramic fiber be recycled or disposed of safely?

Used ceramic fiber is often classified as non-hazardous waste but should be disposed of according to local regulations. Recycling options are limited due to the high-temperature contamination, but some programs may repurpose it for lower-grade applications. Always consult waste management guidelines.