Dusted Asbestos

What Is Dusted Asbestos?

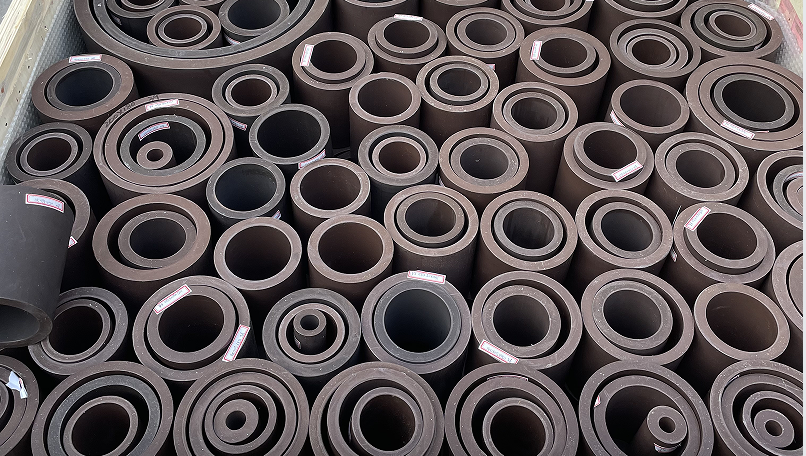

Dusted Asbestos is a finely powdered form of asbestos mineral, processed to meet industrial standards for heat resistance, durability, and insulation properties. It is derived from naturally occurring asbestos ore, milled to achieve a consistent particle size ideal for various applications. Our product undergoes rigorous quality control to ensure it is free from impurities and optimized for performance in high-temperature environments. It is commonly used in construction, manufacturing, and protective coatings due to its exceptional fireproofing and insulating capabilities.

Key Product Parameters

Our Dusted Asbestos is characterized by precise specifications to guarantee reliability and safety in usage. Below are the detailed parameters presented in a list and table format for clarity.

List of Parameters

- Particle Size: Ranging from 0.1 to 10 micrometers, with a median size of 5 micrometers for optimal dispersion.

- Purity Level: Minimum 98% asbestos content, with non-fibrous impurities below 2%.

- Density: Approximately 2.5 g/cm³, ensuring easy handling and application.

- Thermal Resistance: Withstands temperatures up to 1000°C without degradation.

- Moisture Content: Less than 1% by weight to prevent clumping and maintain flowability.

- Color: Off-white to gray, depending on the source ore batch.

- Packaging: Available in 25 kg bags, 50 kg drums, or bulk shipments with customizable options.

Table of Specifications

| Parameter | Value | Testing Method |

|---|---|---|

| Asbestos Type | Chrysotile | X-ray diffraction |

| Fiber Length | 0.5 - 5 mm | Microscopic analysis |

| pH Level | 7.0 - 8.5 (neutral to slightly alkaline) | pH meter testing |

| Bulk Density | 0.4 - 0.6 g/cm³ | ASTM D1895 |

| Ignition Loss | < 3% | Gravimetric analysis |

| Solubility | Insoluble in water and organic solvents | Standard solubility tests |

Applications of Dusted Asbestos

Dusted Asbestos is utilized across multiple industries for its superior properties. In construction, it is integrated into cement products, fireproof boards, and insulation materials to enhance structural integrity and safety. Manufacturing sectors apply it in gaskets, brakes, and clutch linings for its friction resistance. Additionally, it serves as a filler in plastics and coatings to improve heat deflection and durability. Proper handling and adherence to safety guidelines are essential to mitigate health risks associated with airborne fibers.

FAQ Section

What is the primary use of Dusted Asbestos?

Dusted Asbestos is primarily used for insulation and fireproofing in buildings, industrial equipment, and automotive parts due to its high thermal resistance and durability.

Is Dusted Asbestos safe to handle?

When handled with appropriate safety measures, such as using personal protective equipment (PPE) like respirators and gloves, and ensuring proper ventilation, risks can be minimized. However, prolonged exposure to airborne fibers may pose health hazards, so compliance with occupational safety regulations is crucial.

How should Dusted Asbestos be stored?

Store in a cool, dry place away from moisture and direct sunlight. Keep containers tightly sealed to prevent contamination and fiber release. Follow local regulations for hazardous material storage.

Can Dusted Asbestos be used in residential applications?

Due to potential health risks, its use in residential settings is restricted in many regions. It is more commonly applied in industrial and commercial projects where controlled environments and safety protocols are in place.

What are the alternatives to Dusted Asbestos?

Alternatives include fiberglass, mineral wool, and cellulose-based materials, which offer similar insulation properties but with lower health risks. However, these may not match the complete performance profile of asbestos in high-temperature applications.

How is the quality of Dusted Asbestos ensured?

Quality is maintained through regular testing for particle size, purity, and moisture content, using methods like sieve analysis, X-ray fluorescence, and loss on drying tests. Certificates of analysis are provided with each batch.

What is the shelf life of Dusted Asbestos?

When stored properly, it has an indefinite shelf life as it does not degrade over time. However, monitor for moisture absorption, which can affect usability.

Are there any shipping restrictions for Dusted Asbestos?

Yes, international and local shipping regulations may apply due to its classification as a hazardous material. Always check with carriers and authorities for compliance requirements, including labeling and documentation.