News & Events

22 2021-05

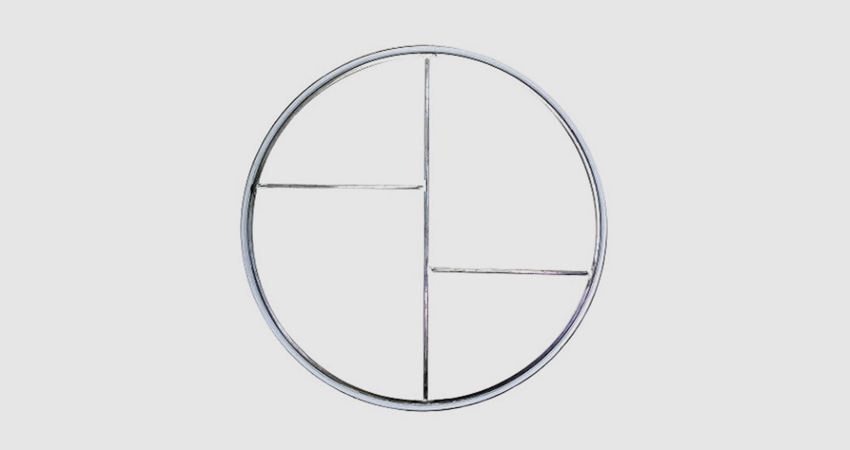

22 2021-05 Sheet gaskets

The premise is simple in that a sheet of material has the gasket shape "punched out" of it. This leads to a very crude, fast and cheap gasket. In previous times the material was compressed asbestos, but in modern times a fibrous material such as high temp graphite is used.

22 2021-05

22 2021-05 Solid material gaskets

The idea behind solid material is to use metals which cannot be punched out of sheets but are still cheap to produce. These gaskets generally have a much higher level of quality control than sheet gaskets and generally can withstand much higher temperatures and pressures.

22 2021-05

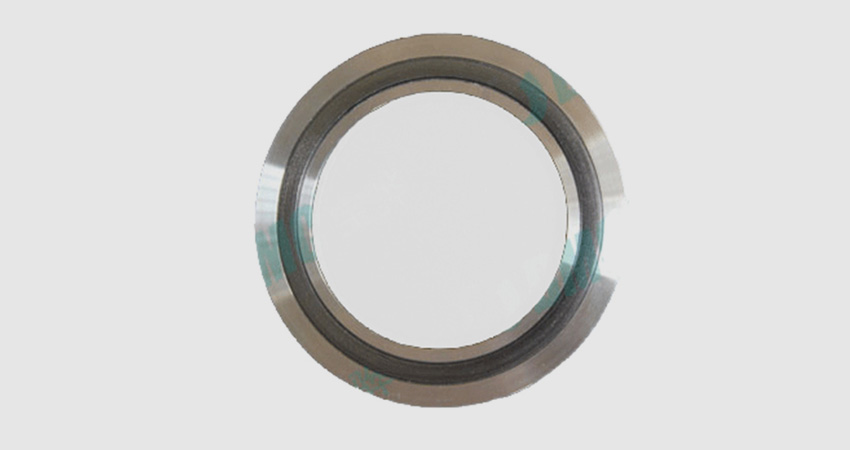

22 2021-05 Spiral-wound gaskets

Spiral-wound gaskets comprise a mix of metallic and filler material. Generally, the gasket has a metal (normally carbon rich or stainless steel) wound outwards in a circular spiral (other shapes are possible) with the filler material (generally a flexible graphite)

22 2021-05

22 2021-05 Constant seating stress gaskets

The constant seating stress gasket consists of two components; a solid carrier ring of a suitable material, such as stainless steel, and two sealing elements of some compressible material installed within two opposing channels,

22 2021-05

22 2021-05 Double-jacketed gaskets

Double-jacketed gaskets are another combination of filler material and metallic materials. In this application, a tube with ends that resemble a "C" is made of the metal with an additional piece made to fit inside of the "C" making the tube thickest at the meeting points.

22 2021-05

22 2021-05 Kammprofile gaskets

Kammprofile gaskets are used in many older seals since they have both a flexible nature and reliable performance. Kammprofiles work by having a solid corrugated core with a flexible covering layer.