Synthetic Fiber Packing

What is Synthetic Fiber Packing?

Synthetic fiber packing is a high-performance sealing material designed for demanding industrial applications. It is engineered from advanced man-made fibers, offering superior resistance to abrasion, chemicals, and extreme temperatures. This type of packing is widely used in pumps, valves, and mixers to prevent leaks and ensure operational efficiency. Its versatility makes it suitable for various industries, including chemical processing, oil and gas, water treatment, and power generation. With proper installation and maintenance, synthetic fiber packing provides long-lasting service, reducing downtime and maintenance costs.

Key Features and Benefits

- Excellent chemical resistance against acids, alkalis, and solvents

- High tensile strength and durability for extended service life

- Low friction coefficient, reducing wear on equipment shafts

- Thermal stability, operating effectively from -100°F to 600°F (-73°C to 316°C)

- Environmentally friendly options available, free from asbestos and other hazardous materials

- Easy to install and maintain, with minimal training required

Product Parameters and Specifications

Our synthetic fiber packing comes in various grades to meet specific application needs. Below is a detailed table of parameters for our standard product line.

| Parameter | Value Range | Unit | Notes |

|---|---|---|---|

| Material Composition | Aramid, Carbon, Graphite, PTFE | - | Custom blends available |

| Temperature Range | -100 to 600 | °F | Depends on fiber type |

| Pressure Rating | Up to 1500 | psi | For dynamic applications |

| pH Resistance | 0 - 14 | - | Full range compatibility |

| Density | 1.2 - 2.0 | g/cm³ | Varies by product grade |

| Tensile Strength | 50 - 200 | MPa | High for abrasive environments |

| Standard Sizes | 1/4" to 1" | inch | Other sizes on request |

Applications of Synthetic Fiber Packing

- Centrifugal and reciprocating pumps in chemical plants

- Valves in oil and gas pipelines

- Mixers and agitators in pharmaceutical manufacturing

- Boiler feed pumps in power generation facilities

- Water and wastewater treatment systems

Installation Guidelines

Proper installation is crucial for optimal performance. Follow these steps:

- Clean the stuffing box thoroughly to remove old packing and debris.

- Measure and cut the synthetic fiber packing to the correct length, ensuring a precise fit.

- Install the rings staggered at 90-degree angles to prevent leakage paths.

- Tighten the gland evenly, avoiding over-compression which can cause excessive heat.

- Run the equipment and adjust the tension as needed after a brief break-in period.

FAQ: Common Questions About Synthetic Fiber Packing

What is the typical lifespan of synthetic fiber packing?

The lifespan varies based on application conditions, such as temperature, pressure, and media. Generally, it can last from 6 months to several years with proper maintenance. Regular inspection and adjustment can extend its service life.

Can synthetic fiber packing be used in food-grade applications?

Yes, certain grades made from FDA-approved materials like PTFE are suitable for food and beverage industries. Always verify the material specifications to ensure compliance with relevant standards.

How does synthetic fiber packing compare to traditional asbestos packing?

Synthetic fiber packing offers superior safety and performance without the health risks associated with asbestos. It provides better chemical resistance, higher temperature tolerance, and is environmentally friendly.

What maintenance is required for synthetic fiber packing?

Regular checks for leaks and wear are essential. Adjust gland tension periodically and lubricate if recommended by the manufacturer. Replace packing when signs of excessive wear or leakage occur.

Is synthetic fiber packing reusable?

No, it is not designed for reuse. Once removed, it should be discarded and replaced with new packing to ensure a proper seal and avoid contamination.

Can it handle high-speed rotational equipment?

Yes, synthetic fiber packing is engineered for high-speed applications, offering low friction and excellent heat dissipation. However, selection should match the specific speed and load conditions.

What are the signs that packing needs replacement?

Increased leakage, higher operating temperatures, and visible wear or fraying are common indicators. Addressing these promptly prevents equipment damage.

Are there custom options available for unique applications?

Absolutely. We offer custom blending and sizing to meet special requirements, such as extreme temperatures or aggressive chemicals. Contact our technical team for assistance.

- View as

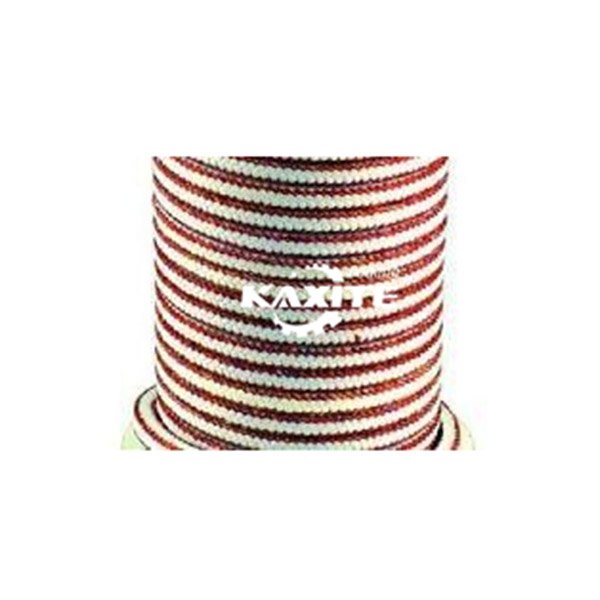

PTFE Packing with Kynol Fiber Corners

PAN Fiber Packing Treated With Graphite

PAN Fiber Packing

Acrylic Fiber Treated With Graphite

Acrylic Fiber Packing