Flange Insulation Gasket Kits Manufacturer in China

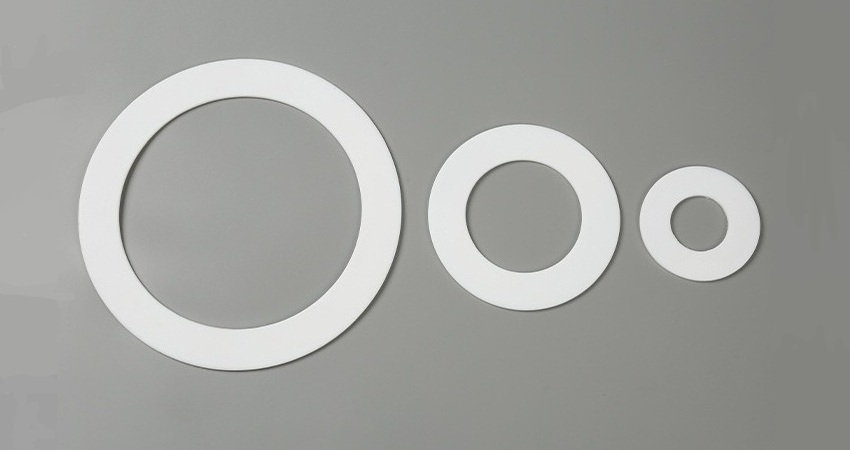

What are Flange Insulation Gasket Kits?

Flange insulation gasket kits are specialized sealing solutions designed to prevent electrical conductivity and corrosion in pipeline systems. These kits are essential for isolating flanges to avoid galvanic corrosion, which can occur when dissimilar metals are in contact in the presence of an electrolyte. They are widely used in industries such as oil and gas, chemical processing, water treatment, and power generation to ensure system integrity and safety.

Key Components of Our Flange Insulation Gasket Kits

Our kits include high-quality materials engineered for durability and performance. Each kit typically contains:

- Insulating gaskets made from non-conductive materials like PTFE, rubber, or composite polymers.

- Insulating sleeves and washers to isolate bolts and nuts from the flange surfaces.

- Sealing elements to ensure a tight, leak-proof connection.

- Additional components such as alignment pins or installation tools for ease of use.

Detailed Product Parameters

Below is a table outlining the standard specifications for our flange insulation gasket kits, tailored to various industrial applications.

| Parameter | Description | Standard Values |

|---|---|---|

| Material | Primary insulating material used in gaskets | PTFE, EPDM, Neoprene, Composite Polymers |

| Temperature Range | Operating temperature limits | -50°C to 260°C (-58°F to 500°F) |

| Pressure Rating | Maximum pressure the kit can withstand | Up to 1500 PSI (10.34 MPa) |

| Size Range | Available flange sizes | 1/2 inch to 24 inches (DN15 to DN600) |

| Thickness | Gasket thickness for insulation | 1.5 mm to 3.0 mm |

| Dielectric Strength | Electrical insulation capability | ≥ 5 kV/mm |

| Chemical Resistance | Resistance to chemicals and corrosion | High resistance to acids, alkalis, and solvents |

Applications of Flange Insulation Gasket Kits

These kits are critical in environments where electrical isolation is necessary to prevent corrosion and ensure safety. Common applications include:

- Pipeline systems in oil refineries to isolate cathodic protection systems.

- Water and wastewater treatment plants to avoid stray current corrosion.

- Chemical processing industries for handling corrosive fluids.

- Power generation facilities, including nuclear and thermal plants.

- Marine and offshore structures to protect against seawater corrosion.

Benefits of Using Our Flange Insulation Gasket Kits

Our products offer numerous advantages:

- Extended equipment lifespan by preventing galvanic corrosion.

- Enhanced safety through reliable electrical isolation.

- Reduced maintenance costs and downtime.

- Compliance with industry standards such as ASTM, ISO, and ASME.

- Easy installation with pre-assembled kits for various flange types.

FAQs About Flange Insulation Gasket Kits

What is the purpose of a flange insulation gasket kit?

Flange insulation gasket kits are used to electrically isolate flanges in piping systems, preventing galvanic corrosion caused by dissimilar metals and ensuring system longevity and safety.

How do I select the right kit for my application?

Consider factors such as operating temperature, pressure, chemical exposure, flange size, and material compatibility. Refer to the product parameters table or consult with our technical team for guidance.

Can these kits be used in high-temperature environments?

Yes, our kits are designed with materials like PTFE that can withstand temperatures up to 260°C (500°F), making them suitable for high-temperature applications.

Are flange insulation gasket kits reusable?

Generally, they are not reusable due to compression and potential damage during disassembly. It is recommended to replace them during maintenance to ensure optimal performance.

What standards do your products comply with?

Our kits meet international standards such as ASTM F436 for insulation washers, ISO 9001 for quality management, and ASME B16.5 for flange dimensions, ensuring reliability and compliance.

How do I install a flange insulation gasket kit?

Installation involves cleaning the flange surfaces, placing the insulating gasket, adding sleeves and washers to bolts, and tightening to the specified torque. Always follow the manufacturer's instructions for best results.

What maintenance is required for these kits?

Regular inspections for signs of wear, corrosion, or damage are recommended. Replace kits during scheduled maintenance to prevent failures and maintain insulation integrity.