Gasket Materials

Understanding Gasket Materials: A Comprehensive Guide

When it comes to industrial and mechanical applications, the choice of Gasket Materials is crucial for ensuring leak-proof seals, durability, and performance under various conditions. Gasket materials serve as sealing elements between two or more mating surfaces, preventing the escape of fluids or gases. This guide delves deep into the key aspects of gasket materials, including types, properties, applications, and frequently asked questions, to help you make informed decisions for your projects.

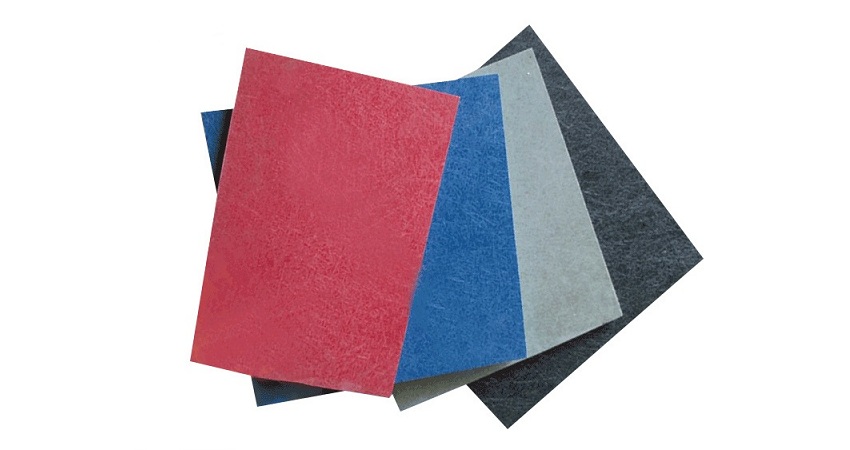

Types of Gasket Materials

Gasket materials can be broadly categorized based on their composition and intended use. Here are the most common types:

- Rubber Gaskets: Made from materials like EPDM, Nitrile, or Silicone, these are flexible and resistant to weathering, making them ideal for automotive and outdoor applications.

- Metal Gaskets: Constructed from stainless steel, copper, or aluminum, these offer high strength and temperature resistance, commonly used in high-pressure systems like pipelines and engines.

- Fiber Gaskets: Composed of materials such as cellulose or aramid fibers, these are cost-effective and suitable for low to medium pressure environments.

- PTFE Gaskets: Made from polytetrafluoroethylene, these provide excellent chemical resistance and are often used in corrosive environments.

- Compressed Non-Asbestos Gaskets: A safer alternative to asbestos, these are durable and resistant to heat and chemicals, widely used in industrial settings.

Key Parameters and Specifications

To select the right gasket material, it's essential to consider various parameters. Below is a detailed table outlining the critical specifications for common gasket materials:

| Material Type | Temperature Range (°C) | Pressure Resistance (PSI) | Chemical Resistance | Common Applications |

|---|---|---|---|---|

| EPDM Rubber | -40 to 150 | Up to 150 | Good resistance to weather, ozone, and water | Automotive systems, HVAC |

| Stainless Steel | -200 to 800 | Up to 5000 | Excellent resistance to corrosion and oxidation | High-temperature pipelines, engines |

| Cellulose Fiber | -30 to 120 | Up to 200 | Fair resistance to oils and solvents | General purpose sealing, plumbing |

| PTFE | -200 to 260 | Up to 1000 | Exceptional resistance to chemicals and acids | Chemical processing, pharmaceuticals |

| Compressed Non-Asbestos | -40 to 400 | Up to 1500 | Good resistance to heat and chemicals | Industrial machinery, boilers |

In addition to these parameters, other factors like thickness, density, and compression set should be evaluated based on specific application requirements. For instance, thicker gaskets may be needed for uneven surfaces, while higher density materials offer better sealing under high pressure.

Applications of Gasket Materials

Gasket materials are ubiquitous across industries. Here's a list of common applications:

- Automotive Industry: Used in engine gaskets, exhaust systems, and fluid seals to prevent leaks and ensure efficiency.

- Oil and Gas: Essential for pipeline flanges, valves, and pumps where high pressure and corrosive fluids are present.

- Chemical Processing: Employed in reactors, tanks, and piping systems to handle aggressive chemicals safely.

- HVAC Systems: Utilized in air handling units and refrigeration to maintain airtight seals and energy efficiency.

- Food and Beverage: Food-grade gaskets ensure hygiene and prevent contamination in processing equipment.

Frequently Asked Questions (FAQ) About Gasket Materials

What is the primary function of a gasket material?

The primary function of a gasket material is to create a seal between two or more mating surfaces, preventing the leakage of fluids or gases while accommodating surface imperfections and variations in pressure and temperature.

How do I choose the right gasket material for my application?

To choose the right gasket material, consider factors such as the operating temperature range, pressure conditions, chemical exposure, and the type of fluid or gas being sealed. Refer to material specifications and consult with experts if needed to ensure compatibility and performance.

Can gasket materials be reused?

Most gasket materials are designed for single use because compression and exposure to conditions can degrade their sealing properties. Reusing gaskets may lead to leaks and failures, so it's generally recommended to replace them during maintenance.

What are the signs of gasket failure?

Signs of gasket failure include visible leaks, reduced system performance, unusual noises, or increased energy consumption. Regular inspection and maintenance can help detect issues early and prevent costly downtime.

Are there environmentally friendly gasket materials available?

Yes, there are eco-friendly options such as recycled rubber gaskets or biodegradable materials. Additionally, non-asbestos gaskets are safer for health and the environment compared to traditional asbestos-based materials.

How does temperature affect gasket material performance?

Temperature can significantly impact gasket material performance by causing expansion, contraction, or degradation. Materials must be selected based on their rated temperature range to maintain seal integrity and avoid failures in extreme conditions.

What is the difference between static and dynamic gaskets?

Static gaskets are used between stationary surfaces, such as flanges, and rely on compression for sealing. Dynamic gaskets, like those in engines or pumps, accommodate movement and require materials with flexibility and wear resistance.

Can gasket materials be customized for specific needs?

Yes, gasket materials can be customized in terms of size, shape, thickness, and composition to meet unique application requirements. Manufacturers often offer tailored solutions based on client specifications.

How important is surface finish when installing gaskets?

Surface finish is critical for proper gasket performance. Rough surfaces may require thicker or softer materials to fill imperfections, while smooth surfaces can work with thinner gaskets. Always follow manufacturer guidelines for surface preparation.

What maintenance practices extend the life of gasket materials?

Regular inspection, proper installation without over-tightening, and using the correct material for the application can extend gasket life. Avoid exposure to超出 rated conditions and replace gaskets during scheduled maintenance.