Graphite PTFE Packing

Introduction to Graphite PTFE Packing

Graphite PTFE packing is a high-performance sealing solution designed for demanding industrial applications. It combines the exceptional lubricity and chemical resistance of PTFE (Polytetrafluoroethylene) with the thermal conductivity and stability of graphite. This results in a packing material that excels in high-temperature and high-pressure environments, providing reliable sealing for pumps, valves, and other equipment. Industries such as chemical processing, oil and gas, and power generation rely on this product for its durability and efficiency.

Key Features and Benefits

- Excellent chemical resistance to a wide range of acids, bases, and solvents.

- High thermal stability, operating effectively in temperatures from -100°F to 500°F (-73°C to 260°C).

- Superior lubricity reduces friction and wear on equipment shafts.

- Low permeability minimizes leakage in dynamic and static applications.

- Easy installation and maintenance due to its flexible, braided structure.

- Environmentally friendly, as it does not contain asbestos or other hazardous materials.

Product Parameters and Specifications

Below is a detailed table outlining the technical specifications of Graphite PTFE packing. These parameters are essential for selecting the right product for your application.

| Parameter | Specification | Units |

|---|---|---|

| Material Composition | PTFE fibers with graphite impregnation | - |

| Temperature Range | -100 to 500 | °F |

| Pressure Range | Up to 3000 | psi |

| pH Range | 0 - 14 | - |

| Density | 1.2 - 1.5 | g/cm³ |

| Tensile Strength | 10 - 15 | MPa |

| Compression Set | 15 - 20 | % |

| Thermal Conductivity | 0.25 - 0.35 | W/m·K |

| Available Sizes | 1/8" to 1" (square cross-section) | inches |

Applications of Graphite PTFE Packing

This packing is versatile and suitable for various industries and equipment types. Common applications include:

- Centrifugal pumps in chemical processing plants.

- Valve stems in oil and gas pipelines.

- Mixers and agitators in pharmaceutical manufacturing.

- Boiler feed pumps in power generation facilities.

- Marine equipment exposed to saline environments.

Installation Guidelines

Proper installation is crucial for optimal performance. Follow these steps:

- Clean the shaft or stem thoroughly to remove any old packing or debris.

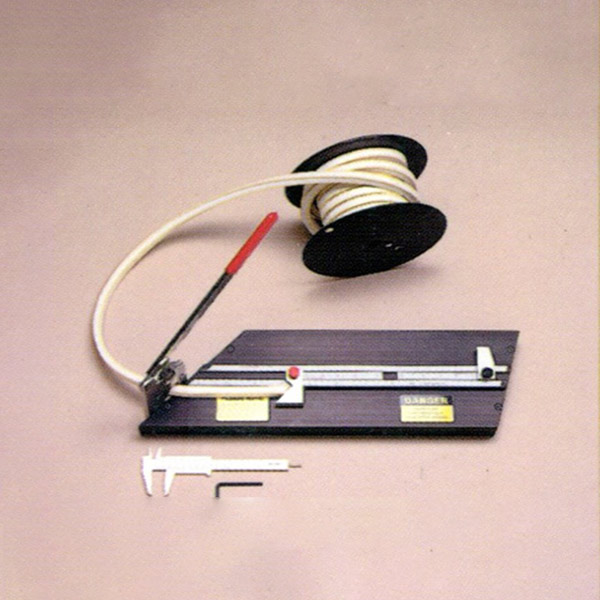

- Measure and cut the packing rings to the required length, ensuring a precise fit.

- Install the rings staggered, with joints offset by at least 90 degrees.

- Tighten the gland evenly, but avoid over-tightening to prevent excessive friction.

- Allow a brief run-in period to let the packing settle and adjust.

Frequently Asked Questions (FAQ)

Q: What is the maximum temperature Graphite PTFE packing can withstand?

A: Graphite PTFE packing can operate continuously at temperatures up to 500°F (260°C), with short-term exposure possible up to 600°F (315°C) depending on the specific conditions and media.

Q: How does graphite enhance the performance of PTFE packing?

A: Graphite improves thermal conductivity, allowing heat to dissipate more efficiently from the packing area, reducing thermal degradation. It also adds lubricity, which minimizes wear and friction, extending the life of both the packing and the equipment.

Q: Is this packing suitable for use with aggressive chemicals?

A: Yes, Graphite PTFE packing offers excellent resistance to a broad spectrum of chemicals, including strong acids, alkalis, and solvents, making it ideal for harsh chemical environments.

Q: Can Graphite PTFE packing be used in food processing applications?

A: While PTFE is generally food-safe, it is essential to verify that the specific product meets FDA or other relevant regulatory standards for food contact. Custom formulations are available for such applications.

Q: What is the typical lifespan of Graphite PTFE packing?

A: The lifespan varies based on operating conditions, such as temperature, pressure, and media. Under standard conditions, it can last several months to years, with proper installation and maintenance.

Q: How do I choose the right size for my equipment?

A: Measure the shaft or stem diameter and the packing space dimensions carefully. Standard sizes range from 1/8" to 1" in square cross-section. Consult the manufacturer's sizing chart or technical support for guidance.

Q: Does Graphite PTFE packing require lubrication during operation?

A: No, it is self-lubricating due to the PTFE and graphite composition, reducing the need for external lubrication and simplifying maintenance.

Q: What are the signs that the packing needs replacement?

A: Increased leakage, higher operating temperatures, or excessive gland adjustments may indicate wear. Regular inspection helps identify these signs early to prevent equipment failure.

Maintenance Tips

To ensure long-lasting performance, adhere to these maintenance practices:

- Regularly inspect the packing for signs of wear or damage.

- Monitor leakage rates and adjust the gland follower as needed, but avoid over-tightening.

- Keep the equipment clean to prevent contamination that could accelerate wear.

- Follow the manufacturer's recommendations for specific media and operating conditions.

Comparison with Other Packing Materials

Graphite PTFE packing offers distinct advantages over traditional materials like asbestos, aramid, or pure PTFE. The table below highlights key differences.

| Material | Temperature Range | Chemical Resistance | Lubricity |

|---|---|---|---|

| Graphite PTFE | -100°F to 500°F | Excellent | High |

| Asbestos | Up to 1000°F | Good | Moderate |

| Aramid | -40°F to 500°F | Good | Low |

| Pure PTFE | -100°F to 500°F | Excellent | High |

Note: Graphite PTFE provides a balanced combination of properties, making it superior for many applications where both thermal and chemical resistance are critical.

- View as

Graphite PTFE Packing with Silicon Rubber Core

Pure Graphite PTFE Packing with Oil

Pure Graphite PTFE Packing

Graphite PTFE Filament Packing