Rubber Sheets Manufacturer & Supplier in China

What is a Rubber Sheet?

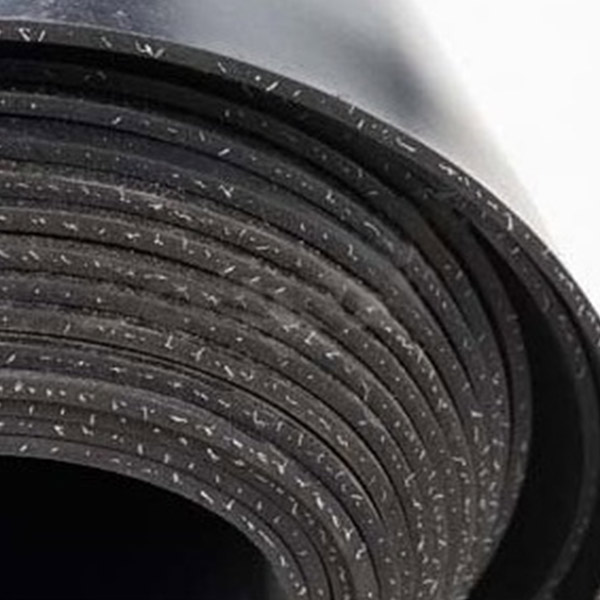

A rubber sheet is a versatile material widely used in industrial, commercial, and residential applications for its excellent properties like flexibility, durability, and resistance to various environmental factors. Made from natural or synthetic rubber compounds, these sheets serve as sealing, insulating, or protective layers in multiple settings, from machinery gaskets to floor coverings. The quality and performance of a rubber sheet depend on its composition, thickness, and specific parameters, which are crucial for selecting the right product for your needs.

Key Parameters of Rubber Sheets

Understanding the technical specifications of rubber sheets ensures optimal performance in their intended applications. Below are the essential parameters detailed in lists and tables for clarity.

Material Types

- Natural Rubber (NR): Offers high tensile strength and elasticity, ideal for dynamic applications.

- Neoprene (CR): Provides good resistance to oils, chemicals, and weather, suitable for outdoor use.

- Nitrile (NBR): Excellent for oil and fuel resistance, commonly used in automotive industries.

- EPDM (Ethylene Propylene Diene Monomer): Superior weather and ozone resistance, perfect for roofing and seals.

- Silicone Rubber: Withstands extreme temperatures (-60°C to 230°C), used in food and medical applications.

- Butyl Rubber: Known for its impermeability to gases, often used in inner tubes and diaphragms.

Physical Properties

| Property | Typical Range | Measurement Standard |

|---|---|---|

| Thickness | 0.5 mm to 50 mm | ASTM D374 |

| Hardness (Shore A) | 30 to 90 | ASTM D2240 |

| Tensile Strength | 10 MPa to 25 MPa | ASTM D412 |

| Elongation at Break | 100% to 800% | ASTM D412 |

| Density | 1.1 g/cm³ to 1.5 g/cm³ | ASTM D297 |

Chemical Resistance

| Chemical | Resistance Level | Recommended Material |

|---|---|---|

| Oils and Greases | Excellent | Nitrile, Neoprene |

| Acids (Dilute) | Good to Excellent | EPDM, Neoprene |

| Alkalis | Good | Natural Rubber, EPDM |

| Water | Excellent | Most types |

| Ozone | Excellent | EPDM, Silicone |

Temperature Range

| Material | Minimum Temperature (°C) | Maximum Temperature (°C) |

|---|---|---|

| Natural Rubber | -50 | 80 |

| Neoprene | -40 | 100 |

| Nitrile | -30 | 120 |

| EPDM | -50 | 150 |

| Silicone | -60 | 230 |

Applications of Rubber Sheets

Rubber sheets are utilized across various industries due to their adaptable properties. Common applications include:

- Gaskets and Seals: Preventing leaks in machinery and automotive systems.

- Flooring and Matting: Providing anti-slip and cushioned surfaces in commercial spaces.

- Insulation: Electrical insulation in wiring and components.

- Protective Linings: Used in tanks and containers to resist chemical corrosion.

- Vibration Dampening: Reducing noise and shock in industrial equipment.

Frequently Asked Questions (FAQ)

What is the typical lifespan of a rubber sheet?

The lifespan depends on the material, environmental conditions, and application. For instance, EPDM rubber sheets can last over 20 years in outdoor settings with minimal degradation, while nitrile sheets in high-oil environments might need replacement every 5-10 years. Proper maintenance, such as cleaning and avoiding extreme temperatures, can extend durability.

How do I choose the right thickness for my project?

Select thickness based on the required pressure resistance, flexibility, and sealing needs. Thinner sheets (0.5-3 mm) are ideal for light-duty gaskets, while thicker ones (10-50 mm) suit heavy-duty applications like industrial matting. Consult technical datasheets and consider factors like compression set and load-bearing capacity.

Can rubber sheets be customized in size and shape?

Yes, most manufacturers offer customization options. Rubber sheets can be cut to specific dimensions, die-cut into shapes, or fabricated with adhesives for easy installation. Provide precise measurements and application details to ensure the custom product meets your requirements.

Are rubber sheets environmentally friendly?

It varies by material. Natural rubber is biodegradable but often blended with synthetics. Synthetic rubbers like neoprene and nitrile are not biodegradable but can be recycled in some programs. Look for eco-friendly options like recycled rubber sheets or those certified by environmental standards.

What maintenance is required for rubber sheets?

Regular cleaning with mild soap and water helps prevent dirt buildup and degradation. Avoid using harsh chemicals that might compromise the material. Inspect for cracks, swelling, or hardness changes periodically, and store in a cool, dry place away from direct sunlight to prolong life.

How does temperature affect rubber sheet performance?

Extreme temperatures can cause hardening, brittleness, or softening. For example, silicone rubber performs well in high heat, while natural rubber may become stiff in cold conditions. Always check the temperature range specified for the material to ensure it suits your environment.

Can rubber sheets be used for food contact applications?

Yes, but only specific types like silicone rubber or FDA-approved nitrile are safe for direct food contact. These materials must meet regulatory standards such as FDA 21 CFR or NSF certifications to ensure they do not leach harmful substances.

What is the difference between solid and foam rubber sheets?

Solid rubber sheets offer dense, impermeable properties ideal for sealing and protection, while foam rubber sheets (like closed-cell or open-cell) provide cushioning, insulation, and lightweight flexibility. Choose based on whether you need compression resistance (solid) or shock absorption (foam).

How do I install a rubber sheet properly?

Clean the surface thoroughly, ensure it is dry and free of debris. For adhesive installation, apply a compatible adhesive evenly and press the sheet firmly, removing air bubbles. For mechanical fastening, use appropriate fixtures without over-tightening to avoid damage. Follow manufacturer guidelines for best results.

What are the signs that a rubber sheet needs replacement?

Look for visible cracks, loss of elasticity, swelling, or changes in hardness. If the sheet no longer provides effective sealing, insulation, or protection, or if it shows signs of chemical degradation like discoloration, it should be replaced to prevent failure.