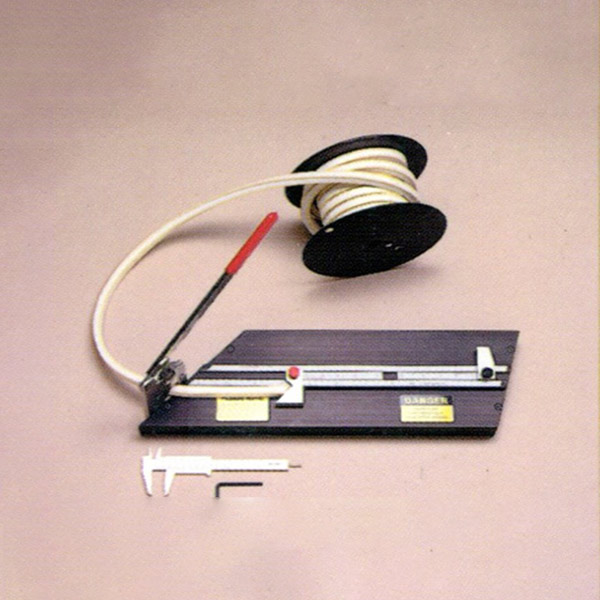

Sealing Tools

Why Choose Professional Sealing Tools?

In industries ranging from construction and plumbing to automotive and manufacturing, reliable sealing is critical for preventing leaks, ensuring safety, and maintaining efficiency. High-quality Sealing Tools are engineered to provide precise application, durability, and consistency, making them indispensable for professionals and DIY enthusiasts alike. This guide offers a detailed overview of sealing tools, including technical specifications, product comparisons, and answers to frequently asked questions, to help you make an informed decision.

Key Parameters of Sealing Tools

Understanding the technical aspects of sealing tools ensures you select the right equipment for your specific needs. Below are the essential parameters to consider:

- Material Composition: Tools are often made from stainless steel, hardened carbon steel, or aluminum alloys to resist corrosion and wear.

- Pressure Rating: Indicates the maximum pressure the tool can handle, typically measured in PSI (pounds per square inch) or BAR.

- Temperature Range: Specifies the operating temperatures, usually from -40°F to 500°F (-40°C to 260°C), suitable for various environments.

- Size and Weight: Dimensions and weight affect portability and ease of use, with compact designs for tight spaces.

- Compatibility: Designed for specific seal types, such as O-rings, gaskets, or hydraulic seals, ensuring proper fit and function.

- Ergonomics: Features like non-slip handles and balanced weight distribution reduce user fatigue during extended use.

Comparison of Popular Sealing Tool Models

To assist in selection, here is a comparison table of common sealing tool models based on key features:

| Model | Material | Pressure Rating | Temperature Range | Weight | Best For |

|---|---|---|---|---|---|

| ProSeal 300X | Stainless Steel | 10,000 PSI | -50°F to 600°F | 2.5 lbs | High-pressure hydraulic systems |

| SealMaster Flexi | Aluminum Alloy | 5,000 PSI | -40°F to 400°F | 1.8 lbs | General plumbing and automotive |

| DuraSeal HeavyDuty | Carbon Steel | 15,000 PSI | -60°F to 700°F | 3.2 lbs | Industrial manufacturing |

| EasySeal Compact | Stainless Steel | 3,000 PSI | -20°F to 300°F | 1.2 lbs | DIY home projects |

Applications of Sealing Tools

Sealing tools are versatile and used across multiple sectors. In plumbing, they ensure watertight connections in pipes and fixtures. Automotive applications involve sealing engine components, transmissions, and fuel systems to prevent leaks and enhance performance. In construction, these tools are vital for sealing windows, doors, and structural joints against weather elements. Industrial settings rely on them for machinery maintenance, hydraulic systems, and pipeline integrity, reducing downtime and costs.

FAQ: Common Questions About Sealing Tools

What types of seals can these tools handle?

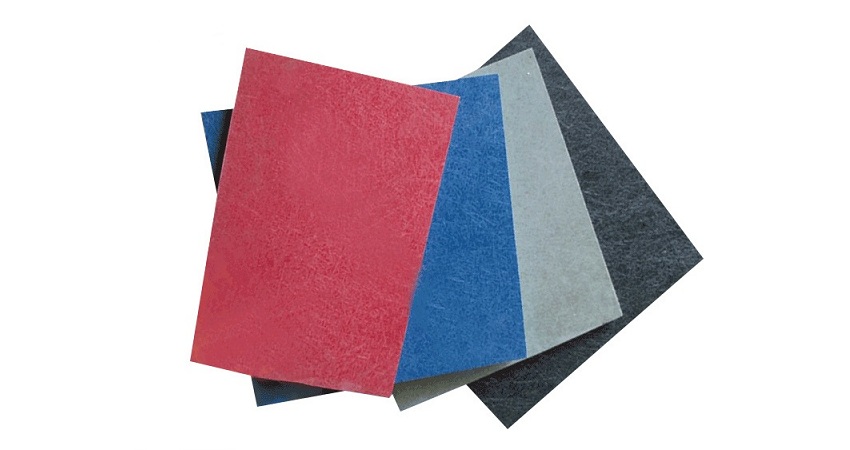

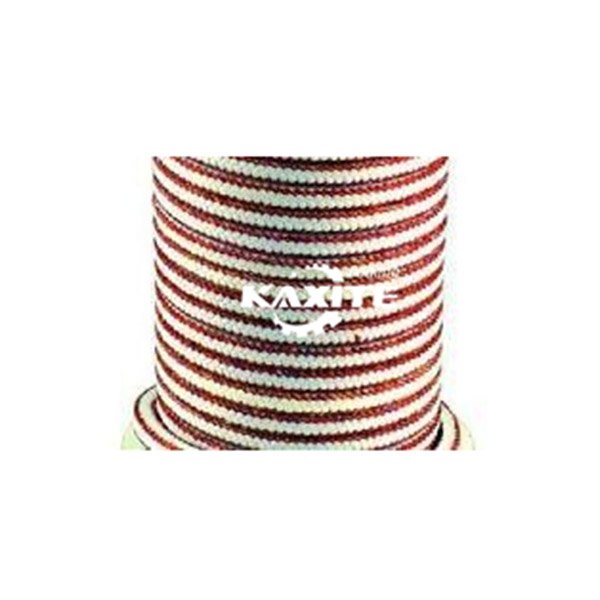

Sealing tools are designed for various seal types, including O-rings, gaskets, lip seals, and mechanical seals. They can be used with materials like rubber, silicone, PTFE, and metals, depending on the tool model. Always check compatibility based on the seal size and application requirements.

How do I maintain my sealing tools for longevity?

Regular maintenance is essential. Clean tools after each use to remove debris and residues. Lubricate moving parts with appropriate oils to prevent corrosion. Store them in a dry, cool place to avoid environmental damage. Inspect for wear and tear periodically, and replace any damaged components to ensure optimal performance.

Can sealing tools be used in high-temperature environments?

Yes, many sealing tools are rated for high temperatures, often up to 500°F or higher, as indicated in their specifications. However, it's crucial to verify the temperature range for your specific tool model and application to avoid failure under extreme conditions.

What safety precautions should I take when using sealing tools?

Always wear protective gear, such as gloves and safety glasses, to prevent injuries from sharp edges or flying debris. Ensure the tool is compatible with the seal material and pressure ratings. Follow manufacturer guidelines for operation, and never exceed the recommended pressure limits to avoid accidents.

Are there electric or pneumatic sealing tools available?

Yes, besides manual tools, electric and pneumatic (air-powered) models are available for high-volume or automated applications. These offer faster operation and consistent results but may require additional equipment like compressors or power sources. Choose based on your workflow and efficiency needs.

How do I choose the right sealing tool for my project?

Consider factors such as the type of seal, operating pressure, temperature conditions, and frequency of use. Refer to the product specifications and compatibility charts. For specialized applications, consult with a professional or manufacturer to ensure the tool meets your specific requirements.

What is the average lifespan of a quality sealing tool?

With proper maintenance, a high-quality sealing tool can last for many years, often 5-10 years or more, depending on usage frequency and conditions. Regular inspection and care significantly extend its lifespan, making it a cost-effective investment.

Can these tools be used for emergency repairs?

Yes, many sealing tools are portable and designed for quick repairs in emergency situations, such as fixing leaks in pipelines or machinery. However, ensure you have the correct tool and seals on hand, and always perform a thorough inspection after repairs to prevent recurrent issues.