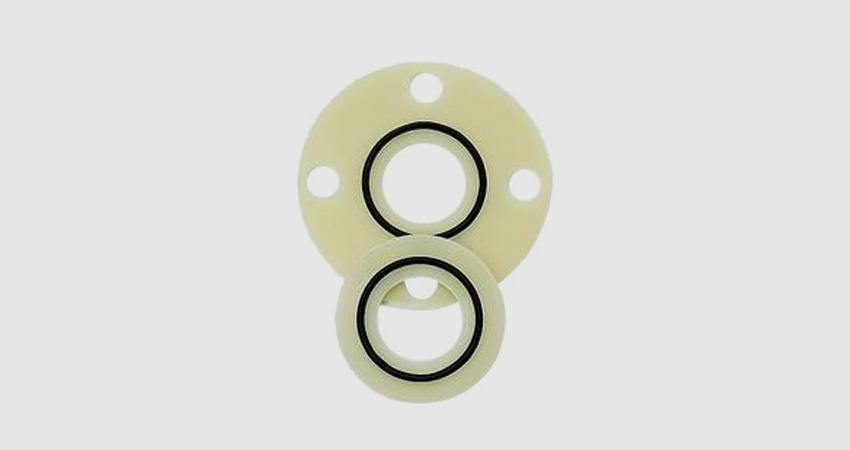

Asbestos Rubber Gaskets

What Are Asbestos Rubber Gaskets?

Asbestos rubber gaskets are sealing components made from a blend of asbestos fibers and rubber compounds. These gaskets are engineered to provide excellent thermal resistance, durability, and sealing capabilities in high-temperature and high-pressure environments. Historically, they have been widely used in industrial applications such as automotive systems, pipelines, boilers, and machinery where heat and chemical resistance are critical. The asbestos fibers contribute to the material's strength and heat tolerance, while the rubber matrix offers flexibility and a tight seal. However, due to health concerns associated with asbestos exposure, modern alternatives are often recommended, though these gaskets remain in use in certain regulated contexts with proper safety measures.

Key Product Parameters of Asbestos Rubber Gaskets

Understanding the specifications of asbestos rubber gaskets is essential for selecting the right product for your needs. Below are the detailed parameters presented in lists and a table for clarity.

Material Composition

- Asbestos Content: Typically ranges from 60% to 85% by weight, providing heat resistance.

- Rubber Compound: Often nitrile rubber (NBR) or natural rubber, offering elasticity and seal integrity.

- Additives: May include fillers, antioxidants, and vulcanizing agents to enhance performance.

Physical Properties

- Density: Approximately 1.5 to 2.0 g/cm³, ensuring robustness without excessive weight.

- Hardness: Measured on the Shore A scale, usually between 50 and 90, indicating flexibility to rigidity based on application.

- Tensile Strength: Ranges from 10 to 20 MPa, providing resistance to tearing under stress.

- Elongation at Break: Typically 200% to 400%, allowing for deformation without failure.

Performance Characteristics

| Parameter | Value Range | Description |

|---|---|---|

| Temperature Resistance | -20°C to 300°C | Suitable for both low and high-temperature environments, with peak performance up to 300°C. |

| Pressure Resistance | Up to 1500 psi | Capable of withstanding high pressures in systems like engines and pipelines. |

| Chemical Resistance | Resistant to oils, acids, and alkalis | Performs well in contact with various chemicals, though compatibility should be verified for specific substances. |

| Compression Set | 15% to 30% | Indicates the ability to maintain seal after compression; lower values are preferable for long-term use. |

Standard Sizes and Dimensions

- Thickness: Available from 1.5 mm to 6 mm, customizable for specific gaps.

- Width: Ranges from 10 mm to 100 mm, depending on application requirements.

- Shape: Can be cut into sheets, strips, or custom die-cut forms like O-rings or flat gaskets.

Applications of Asbestos Rubber Gaskets

Asbestos rubber gaskets are utilized in numerous industries due to their exceptional properties. Common applications include automotive exhaust systems, where they seal joints against hot gases; industrial boilers and heaters, providing insulation and leak prevention; chemical processing equipment, resisting corrosive substances; and piping systems in oil and gas sectors, ensuring secure connections under pressure. Their ability to maintain integrity in extreme conditions makes them ideal for heavy-duty machinery and aerospace components, though users must adhere to safety regulations regarding asbestos handling.

FAQ: Frequently Asked Questions About Asbestos Rubber Gaskets

What are the primary benefits of using asbestos rubber gaskets?

Asbestos rubber gaskets offer high thermal stability, excellent sealing under pressure, and resistance to many chemicals, making them reliable for demanding industrial environments. The asbestos fibers enhance durability and heat tolerance, which is why they were historically favored over pure rubber gaskets.

Are asbestos rubber gaskets safe to use?

Due to the health risks associated with asbestos fibers, such as respiratory diseases and cancer, these gaskets require careful handling. In many regions, their use is restricted or regulated. It is crucial to follow occupational safety guidelines, use personal protective equipment (PPE), and consider asbestos-free alternatives where possible to minimize exposure.

How do I install an asbestos rubber gasket properly?

Installation involves cleaning the mating surfaces thoroughly to remove debris, placing the gasket evenly without stretching, and torquing bolts to the manufacturer's specifications in a crisscross pattern to ensure uniform compression. Avoid over-tightening, as it can damage the gasket and lead to leaks. Always refer to the product's installation manual for specific instructions.

Can asbestos rubber gaskets be used with all types of fluids?

While they resist many oils, acids, and alkalis, compatibility depends on the specific rubber compound and asbestos blend. For instance, they may not be suitable for certain solvents or strong oxidizing agents. Always check the chemical resistance chart provided by the manufacturer and conduct tests if necessary to prevent degradation or failure.

What is the typical lifespan of an asbestos rubber gasket?

The lifespan varies based on operating conditions, such as temperature, pressure, and exposure to chemicals. Under ideal conditions, they can last several years, but in high-stress environments, regular inspection and replacement every 1-2 years may be necessary to ensure safety and performance.

Are there environmentally friendly alternatives to asbestos rubber gaskets?

Yes, modern alternatives include aramid fiber gaskets, graphite-based gaskets, and compressed non-asbestos materials (e.g., cellulose or fiberglass blends). These options provide similar performance without the health risks, though they may differ in cost and specific properties like temperature range.

How should I dispose of old asbestos rubber gaskets?

Disposal must comply with local hazardous waste regulations due to the asbestos content. Typically, this involves sealing the gaskets in approved containers, labeling them as asbestos waste, and using licensed disposal facilities. Never incinerate or discard them in regular trash to avoid environmental contamination and health hazards.

Can asbestos rubber gaskets be customized for specific applications?

Absolutely, manufacturers often offer custom cutting, shaping, and compounding to meet unique requirements. Provide details such as dimensions, temperature ranges, pressure ratings, and chemical exposures to get a gasket tailored for optimal performance in your system.