News

We are glad to share with you about the results of our work, company news,and give you timely developments and personnel appointment and removal conditions.

05 2022-07

05 2022-07 Do you really understand graphite gaskets?

How much do you know about graphite gaskets? Choosing a good graphite gasket not only plays a very important role in industrial pipelines, but also can effectively prevent corrosion. Graphite gaskets must first be made of pure graphite raw materials and pressed. Graphite gaskets are suitable for packing and sealing of various valves, pumps, reaction kettles and other equipment working under high temperature, high pressure and strong corrosive medium.

01 2022-07

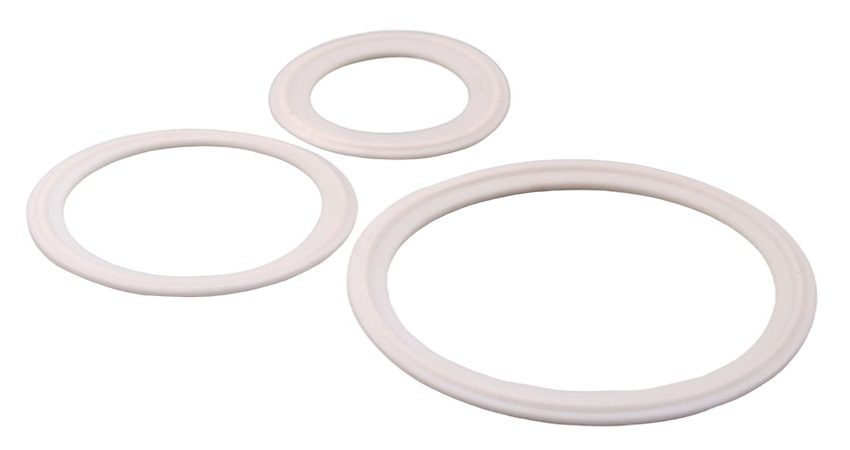

01 2022-07 What are the performance advantages of PTFE gaskets?

High temperature resistance of PTFE gasket: the operating temperature can reach 260℃, low temperature resistance: it has excellent mechanical toughness, the lowest temperature can reach -196℃, the working pressure can reach ≤4.0Mpa, and the elongation rate can reach 5% , It can also resist corrosion to most chemicals and solvents, showing laziness, strong acid and alkali resistance, water and various organic solvents.

29 2022-06

29 2022-06 What are the characteristics of ramie packing?

1. Ramie packing is made of high-quality ramie fiber and fully moisturizing oil, and is specially woven into a square shape. The advantage is that the coefficient of friction is extremely low, the shaft is not worn, and it is anti-corrosion. It can be used in the shipping industry, cold water treatment, sea water and cold oil; low pressure valves, rotating equipment, reciprocating pump hydraulic presses, ship propellers and other equipment.

27 2022-06

27 2022-06 WHAT IS PTFE?

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene.Being hydrophobic, non-wetting, high density and resistant to high temperatures, PTFE is an incredibly versatile material with a wide variety of applications, thought it's perhaps best-known for its non-stick properties.

25 2022-06

25 2022-06 What rubber is mainly used in the market?

1. Natural rubber (NR)

Natural rubber (NR) is an isoprene polymer. Has excellent resilience, tensile strength, elongation, abrasion resistance, tear and compression set properties are superior to most synthetic rubbers. Suitable for making tires, shock absorption parts, buffer ropes and sealing parts. Not resistant to oil, poor weather resistance, ozone and oxygen performance. Use temperature range -60 ~ 100 ℃.

20 2022-06

20 2022-06 Factors for the sealing performance of metal wound gaskets?

Sealing is achieved by compressing the gasket material and filling uneven sealing surfaces. This kind of seal can effectively prevent the leakage of the medium. In order to maintain this working condition, the connection part must exert enough load to resist the end-face hydrostatic pressure caused by the internal pressure of the system. The use of gaskets depends on many factors. Let's introduce the factors that affect the sealing performance of stainless steel metal spiral wound gaskets.