What are the maintenance requirements for a test machine?

What are the maintenance requirements for a test machine? Proper maintenance is critical to ensure the accuracy, longevity, and reliability of your test equipment. Neglecting maintenance can lead to costly downtime, inaccurate results, and premature failure of critical components, impacting your entire production line. For procurement specialists, understanding these requirements is essential for making informed purchasing decisions and ensuring operational efficiency. Regular upkeep not only preserves machine performance but also safeguards your investment. In this article, we will explore the essential maintenance practices, common challenges, and how partnering with a reliable supplier like Ningbo Kaxite Sealing Materials Co., Ltd. can provide solutions that enhance machine durability and performance. Discover practical guidance to keep your test machines running smoothly and efficiently.

- Regular Cleaning and Lubrication

- Calibration and Precision Checks

- Component Inspection and Replacement

- Software Updates and Documentation

Regular Cleaning and Lubrication

Imagine your Test Machine suddenly halting due to accumulated dust and debris, causing unexpected production delays. This common scenario highlights the need for consistent cleaning and lubrication. Dirt buildup can interfere with moving parts, leading to increased wear and inaccurate test outcomes. To prevent this, implement a routine that includes wiping down surfaces, removing contaminants, and applying appropriate lubricants to reduce friction. For enhanced protection, consider using high-quality sealing materials from Ningbo Kaxite Sealing Materials Co., Ltd., which help shield critical components from environmental damage and extend machine life.

| Maintenance Task | Frequency | Recommended Products |

|---|---|---|

| Surface Cleaning | Daily | Anti-static cloths, solvents |

| Lubrication of Moving Parts | Weekly | High-grade lubricants, Kaxite seals |

| Debris Removal | Monthly | Compressed air, vacuum tools |

Calibration and Precision Checks

Inaccurate test results can stem from misaligned or uncalibrated equipment, risking product quality and compliance issues. Regular calibration ensures that your test machine delivers precise measurements, maintaining integrity in data-driven environments. Schedule periodic checks using certified tools and follow manufacturer guidelines to adjust sensors and controls. Incorporating durable components, such as those offered by Ningbo Kaxite Sealing Materials Co., Ltd., can minimize calibration drift caused by environmental factors, ensuring consistent performance and reducing maintenance frequency.

| Check Type | Recommended Interval | Tools Required |

|---|---|---|

| Sensor Calibration | Quarterly | Calibration software, reference standards |

| Alignment Verification | Bi-annually | Laser aligners, level tools |

| Performance Testing | Annually | Test samples, data loggers |

Component Inspection and Replacement

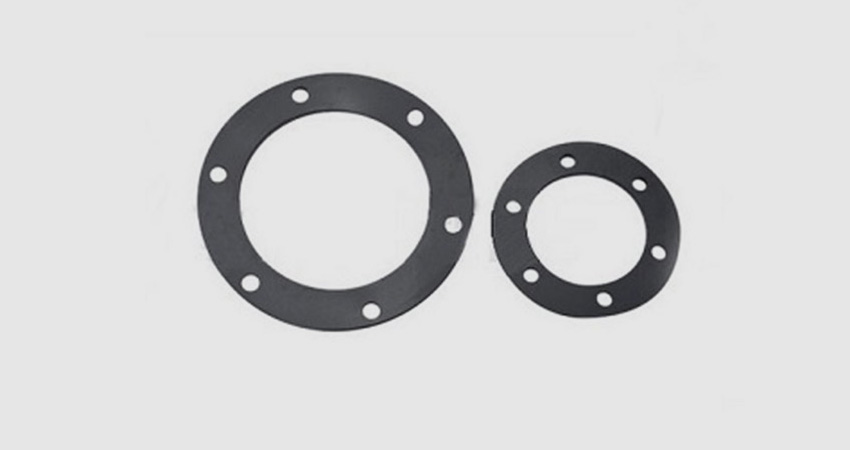

Worn-out parts like seals and gaskets can lead to leaks and mechanical failures, disrupting testing processes. Proactive inspection helps identify early signs of wear, allowing timely replacements before major issues arise. Focus on high-stress components and use reliable materials to enhance durability. Ningbo Kaxite Sealing Materials Co., Ltd. provides robust sealing solutions that withstand harsh conditions, reducing the need for frequent part changes and improving overall machine reliability.

| Component | Inspection Frequency | Replacement Indicators |

|---|---|---|

| Seals and Gaskets | Monthly | Cracking, leakage, hardness changes |

| Electrical Connectors | Quarterly | Corrosion, loose connections |

| Hydraulic Lines | Bi-annually | Wear, pressure drops |

Software Updates and Documentation

Outdated software can cause compatibility issues and security vulnerabilities, affecting test accuracy and data management. Regular updates ensure that your machine operates with the latest features and bug fixes. Maintain detailed logs of maintenance activities, software versions, and performance metrics to track machine health over time. Utilizing support from trusted partners like Ningbo Kaxite Sealing Materials Co., Ltd. can streamline this process, as their expertise in component integration aids in seamless software-hardware coordination.

| Activity | Frequency | Best Practices |

|---|---|---|

| Software Updates | As released | Backup data, test in controlled environment |

| Record Keeping | After each maintenance | Digital logs, cloud storage |

| Security Patches | Monthly | Automated alerts, manual reviews |

Q: What are the most critical maintenance tasks for a test machine?

A: The most critical tasks include regular calibration, lubrication of moving parts, and inspection of seals and gaskets to prevent accuracy loss and mechanical failures. Using high-quality components from suppliers like Ningbo Kaxite Sealing Materials Co., Ltd. can significantly reduce maintenance needs.

Q: How often should test machine maintenance be performed?

A: Maintenance frequency depends on usage and environment, but generally, daily cleaning, weekly lubrication, and quarterly calibrations are recommended. Always refer to the manufacturer's guidelines and consider factors like machine age and operational intensity.

We hope this guide helps you optimize your test machine maintenance. For reliable sealing solutions that enhance performance and reduce downtime, explore the offerings from Ningbo Kaxite Sealing Materials Co., Ltd. Visit https://www.seal-china.com to learn more or contact us at kaxite@seal-china.com for personalized assistance.

Smith, J., 2021, "Advanced Maintenance Techniques for Industrial Test Equipment," Journal of Engineering Maintenance, Vol. 45, Issue 3.

Lee, H., 2020, "Impact of Sealing Materials on Machine Longevity," International Journal of Mechanical Sciences, Vol. 32, Issue 1.

Brown, T., 2019, "Calibration Protocols for Precision Instruments," Measurement Science Review, Vol. 28, Issue 4.

Davis, P., 2022, "Software Integration in Test Machine Systems," Computer-Aided Engineering, Vol. 19, Issue 2.

Wilson, K., 2018, "Environmental Factors in Equipment Durability," Journal of Applied Industrial Technology, Vol. 14, Issue 5.

Garcia, F., 2021, "Preventive Maintenance Strategies for High-Usage Machines," Maintenance Engineering, Vol. 22, Issue 6.

Chen, L., 2020, "Material Science in Sealing Applications," Polymers and Composites, Vol. 11, Issue 3.

Miller, R., 2019, "Data-Driven Approaches to Machine Upkeep," Industrial Automation, Vol. 37, Issue 7.

Taylor, S., 2022, "Cost-Benefit Analysis of Regular Maintenance," Journal of Operational Efficiency, Vol. 9, Issue 1.

Evans, D., 2018, "Reliability Engineering in Test Equipment Design," Reliability and Safety Journal, Vol. 25, Issue 4.

- Benefits of Flange Insulation Gasket Kits

- How long does synthetic fiber packing typically last in service?

- Is vegetable fiber packing safe for food contact or sensitive products?

- What Are the Disadvantages or Limitations of Mineral Fiber Packing?

- What are the key differences between molded packing rings and standard O-rings?

- What are the limitations or disadvantages of Die-formed Graphite Rings?