PTFE Tube

Introduction to PTFE Tube

PTFE Tube, or Polytetrafluoroethylene Tube, is a highly versatile and durable fluoropolymer tubing known for its exceptional chemical resistance, high-temperature stability, and low friction properties. Widely used in industries such as automotive, aerospace, medical, and chemical processing, PTFE tubes offer reliable performance in demanding environments. This guide provides a detailed overview of product parameters, specifications, and common FAQs to help you make an informed decision.

Key Features of PTFE Tube

- Excellent chemical resistance to acids, bases, and solvents

- Operating temperature range from -200°C to 260°C

- Low coefficient of friction for smooth fluid transfer

- Non-stick and anti-adhesive properties

- High dielectric strength for electrical insulation

- FDA compliant for food and medical applications

- UV and weather resistant for outdoor use

Product Parameters and Specifications

Our PTFE tubes are manufactured to meet strict industry standards. Below is a table summarizing key specifications:

| Parameter | Specification | Units |

|---|---|---|

| Inner Diameter (ID) | 0.5 - 50 | mm |

| Outer Diameter (OD) | 1 - 60 | mm |

| Wall Thickness | 0.2 - 10 | mm |

| Length | Custom up to 1000 | mm |

| Color | Natural (white), black, or custom | - |

| Tensile Strength | 20 - 35 | MPa |

| Elongation at Break | 300 - 500 | % |

| Dielectric Strength | >20 | kV/mm |

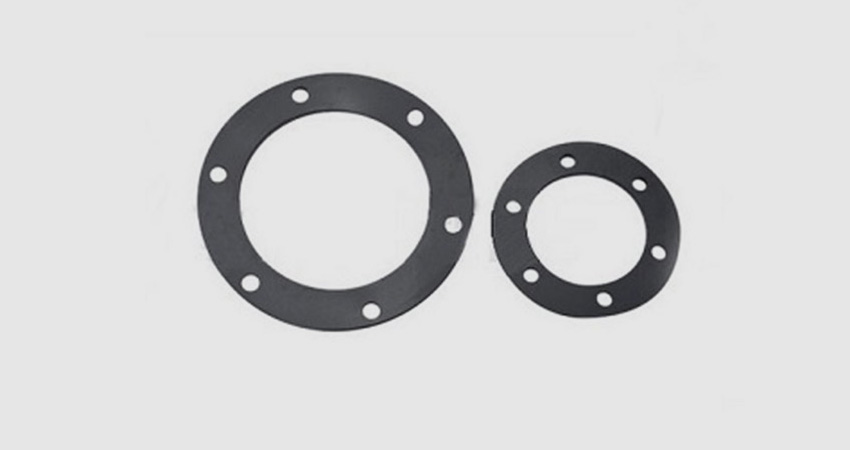

Applications of PTFE Tube

- Chemical transfer lines in industrial settings

- Medical tubing for catheters and fluid delivery

- Electrical insulation for wiring and components

- Food and beverage processing equipment

- Automotive fuel and brake lines

- Aerospace hydraulic systems

- Laboratory apparatus and analytical instruments

FAQs About PTFE Tube

What is the maximum temperature a PTFE tube can withstand?

PTFE tubes can continuously operate at temperatures up to 260°C (500°F) and briefly withstand peaks up to 300°C (572°F) without degrading, making them ideal for high-heat applications.

Are PTFE tubes resistant to all chemicals?

PTFE tubes exhibit excellent resistance to most chemicals, including strong acids, bases, and organic solvents. However, they may not be suitable for use with molten alkali metals or certain fluorinated compounds at high temperatures.

Can PTFE tubes be used for food contact applications?

Yes, PTFE is FDA compliant and often used in food processing and medical devices due to its non-toxic, non-stick, and easy-to-clean properties, ensuring safety and hygiene.

How do I choose the right wall thickness for my application?

Wall thickness selection depends on pressure requirements, flexibility needs, and chemical exposure. Thicker walls offer higher pressure ratings but reduced flexibility, while thinner walls are more bendable but suited for lower pressures.

Is PTFE tubing flexible or rigid?

PTFE tubing is semi-rigid and maintains its shape well, but it can be bent and flexed without kinking, especially in thinner wall variants, providing a balance of durability and maneuverability.

Does PTFE tube have any electrical properties?

PTFE is an excellent electrical insulator with high dielectric strength, low dielectric constant, and low dissipation factor, making it perfect for wiring, capacitors, and other electronic applications.

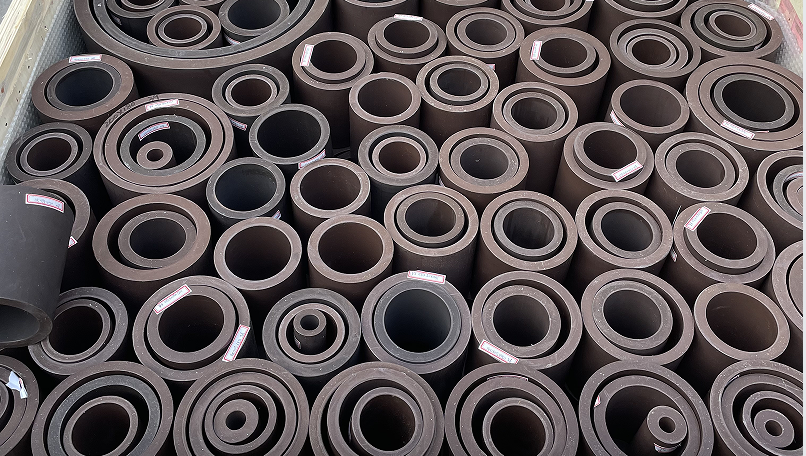

How is PTFE tubing manufactured?

PTFE tubing is typically produced through extrusion processes, where fine powder is compressed and sintered at high temperatures to form a continuous tube, ensuring consistent dimensions and properties.

Can PTFE tubes be custom-colored?

Yes, custom colors are available by adding compatible pigments during manufacturing, though natural white is standard. This is useful for coding or aesthetic purposes in various industries.

What is the shelf life of PTFE tubing?

PTFE tubing has an virtually indefinite shelf life when stored in a cool, dry place away from direct sunlight and extreme temperatures, as it does not degrade or become brittle over time.

Are there any alternatives to PTFE tubing?

Alternatives include FEP, PFA, or silicone tubing, but PTFE offers superior temperature and chemical resistance. The choice depends on specific application requirements like flexibility or cost.

Additional Technical Details

For specialized applications, our PTFE tubes can be reinforced or lined with other materials to enhance performance. Custom sizes and certifications (e.g., USP Class VI for medical use) are available upon request. Always consult technical datasheets for precise compatibility and performance data.

- View as

25% Bronze Powder Filled Teflon PTFE Tube

Graphite Filled PTFE Tube

Bronze Powder Filled PTFE Tube

Carbon Fiber Filled PTFE Tube

5% Glass Fiber Filled PTFE Tube