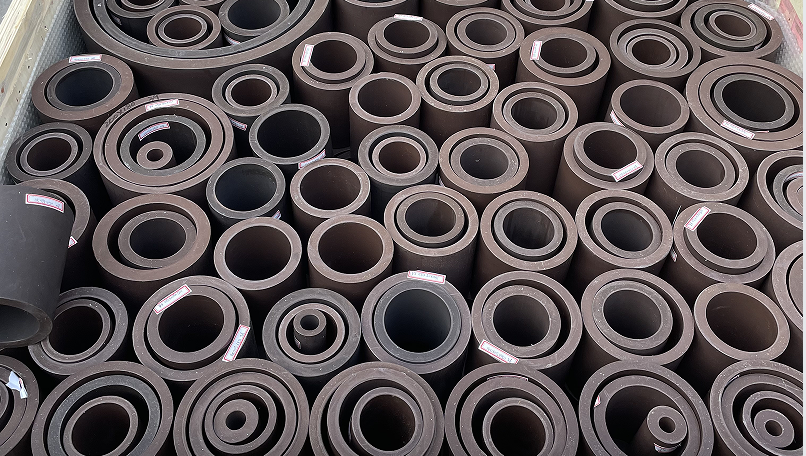

Spiral Wound Gaskets Manufacturer in China

Understanding Spiral Wound Gaskets

Spiral wound gaskets are critical components in industrial sealing applications, designed to provide reliable performance under extreme conditions. These gaskets consist of alternating layers of metal and filler material wound into a spiral form, creating a robust seal that can withstand high pressures, temperatures, and chemical exposures. Industries such as oil and gas, chemical processing, power generation, and petrochemicals rely on spiral wound gaskets for their durability and efficiency. Their versatility makes them suitable for a wide range of flange types and environments, ensuring leak-free operations in critical systems.

Key Parameters of Spiral Wound Gaskets

To select the appropriate spiral wound gasket for your application, it's essential to understand the key parameters that define their performance. These parameters include materials, dimensions, pressure ratings, and temperature ranges. Below, we detail these aspects using lists and tables for clarity.

Material Specifications

Spiral wound gaskets are composed of two primary materials: the metal winding strip and the filler material. The choice of materials depends on the operating conditions, such as temperature, pressure, and media compatibility.

- Metal Winding Strip: Common metals include stainless steel (e.g., 304, 316), carbon steel, monel, and incoloy. Each metal offers specific resistance to corrosion and temperature.

- Filler Material: Fillers such as graphite, PTFE, mica, or ceramic provide sealing properties. Graphite is popular for high-temperature applications, while PTFE is used for chemical resistance.

- Outer Ring: Often made of carbon steel or stainless steel, the outer ring provides compression control and prevents over-tightening.

- Inner Ring: Optional inner rings, typically metal, help prevent erosion and turbulence in the fluid flow.

| Metal Type | Filler Type | Max Temperature (°C) | Max Pressure (Bar) | Common Applications |

|---|---|---|---|---|

| Stainless Steel 304 | Graphite | 500 | 250 | General chemical processing, steam systems |

| Stainless Steel 316 | PTFE | 260 | 150 | Acid and alkali environments, food industry |

| Carbon Steel | Graphite | 550 | 300 | High-pressure oil and gas pipelines |

| Monel | Ceramic | 800 | 200 | Extreme temperature and corrosive media |

Dimensional Specifications

Spiral wound gaskets are available in various sizes to match flange standards like ANSI, DIN, and JIS. Key dimensions include inner diameter (ID), outer diameter (OD), and thickness.

- Inner Diameter (ID): Matches the pipe inner diameter to ensure smooth flow.

- Outer Diameter (OD): Corresponds to the flange outer dimensions for proper seating.

- Thickness: Typically ranges from 3mm to 5mm, affecting compression and seal integrity.

- Width: The radial width of the gasket, influencing the sealing surface area.

| Flange Class | Nominal Pipe Size (NPS) | Inner Diameter (mm) | Outer Diameter (mm) | Thickness (mm) |

|---|---|---|---|---|

| 150 | 2 inch | 52 | 120 | 3.2 |

| 300 | 4 inch | 102 | 190 | 4.5 |

| 600 | 6 inch | 154 | 235 | 4.5 |

| 900 | 8 inch | 202 | 275 | 4.5 |

Performance Ratings

Performance ratings for spiral wound gaskets are determined by factors like pressure-temperature ratings, leakage rates, and compliance with standards such as ASME B16.20.

- Pressure Rating: Expressed in bars or psi, indicating the maximum pressure the gasket can handle without failure.

- Temperature Rating: The upper and lower temperature limits within which the gasket maintains its sealing properties.

- Leakage Class:

- According to ISO 15848, spiral wound gaskets can achieve leakage rates as low as Class A for tight sealing.

| Gasket Type | Max Pressure (Bar) at 20°C | Max Temperature (°C) | Min Temperature (°C) | Leakage Class |

|---|---|---|---|---|

| SS304/Graphite | 250 | 500 | -200 | Class A |

| SS316/PTFE | 150 | 260 | -100 | Class B |

| Carbon Steel/Graphite | 300 | 550 | -50 | Class A |

FAQs About Spiral Wound Gaskets

Frequently asked questions provide insights into common concerns and practical aspects of using spiral wound gaskets. Below is a detailed Q&A section based on industry experience.

What are the main advantages of spiral wound gaskets?

Spiral wound gaskets offer excellent resilience, allowing them to absorb flange movements and vibrations. They provide reliable sealing under high pressure and temperature conditions, with a wide range of material options for chemical compatibility. Their design ensures low leakage rates and long service life, reducing maintenance costs.How do I select the right spiral wound gasket for my application?

Selection depends on several factors: the fluid media (to choose compatible materials), operating pressure and temperature, flange type and standards (e.g., ANSI, DIN), and environmental conditions. Consult manufacturer datasheets and consider standards like ASME B16.20 for guidance. It's also advisable to perform a risk assessment for critical applications.Can spiral wound gaskets be reused?

Generally, spiral wound gaskets are not recommended for reuse due to compression set and potential damage during removal. Reusing them can lead to leaks and failures. Always inspect gaskets before installation and replace them if there are signs of wear, deformation, or chemical attack.What is the proper installation torque for spiral wound gaskets?

The torque value depends on the gasket size, material, and flange class. Refer to the manufacturer's recommendations or standards like ASME PCC-1 for bolt tightening procedures. Uniform bolt loading is crucial to avoid uneven compression, which can cause leaks. Use a calibrated torque wrench and follow a cross-pattern tightening sequence.How do spiral wound gaskets compare to other gasket types?

Compared to flat gaskets or ring-type joints, spiral wound gaskets provide better performance in high-pressure and high-temperature applications due to their flexible, layered structure. They offer superior creep resistance and recovery compared to non-metallic gaskets. However, they may be more expensive and require careful installation.

What maintenance practices are recommended for spiral wound gaskets?

Regular inspection during shutdowns is key. Check for signs of leakage, corrosion, or compression set. Ensure flanges are clean and undamaged before reinstalling. Keep records of operating conditions and gasket performance to predict replacement intervals. Follow proper storage guidelines to prevent damage before use.