Aramid Fiber Packing

Introduction to Aramid Fiber Packing

Aramid fiber packing is a high-performance sealing material widely used in industrial applications due to its exceptional strength, thermal stability, and chemical resistance. It is made from synthetic aramid fibers, which are known for their durability and ability to withstand extreme conditions. This type of packing is ideal for sealing pumps, valves, and other equipment in industries such as chemical processing, oil and gas, and power generation.

Key Features and Benefits

- High tensile strength and abrasion resistance

- Excellent thermal stability, operating temperatures from -100°F to 500°F (-73°C to 260°C)

- Superior chemical resistance to acids, alkalis, and solvents

- Low coefficient of friction, reducing wear on equipment

- Non-conductive and non-magnetic properties

- Long service life, reducing maintenance costs

Product Specifications

Below is a detailed table of specifications for standard aramid fiber packing products:

| Parameter | Value | Unit |

|---|---|---|

| Material Composition | 100% Aramid Fiber | - |

| Density | 0.9 - 1.2 | g/cm³ |

| Tensile Strength | ≥ 3000 | MPa |

| Maximum Operating Temperature | 500 | °F |

| Minimum Operating Temperature | -100 | °F |

| pH Range | 2 - 12 | - |

| Compression Set | < 15 | % |

| Thermal Conductivity | 0.04 - 0.06 | W/m·K |

Applications of Aramid Fiber Packing

- Chemical processing plants for sealing aggressive fluids

- Oil and gas industry in valves and pumps handling hydrocarbons

- Power generation equipment, including turbines and boilers

- Marine applications for sealing shafts and propellers

- Automotive industry in high-temperature environments

- Pharmaceutical manufacturing where cleanliness is critical

Installation Guidelines

Proper installation is crucial for optimal performance of aramid fiber packing. Follow these steps:

- Clean the stuffing box thoroughly to remove old packing and debris.

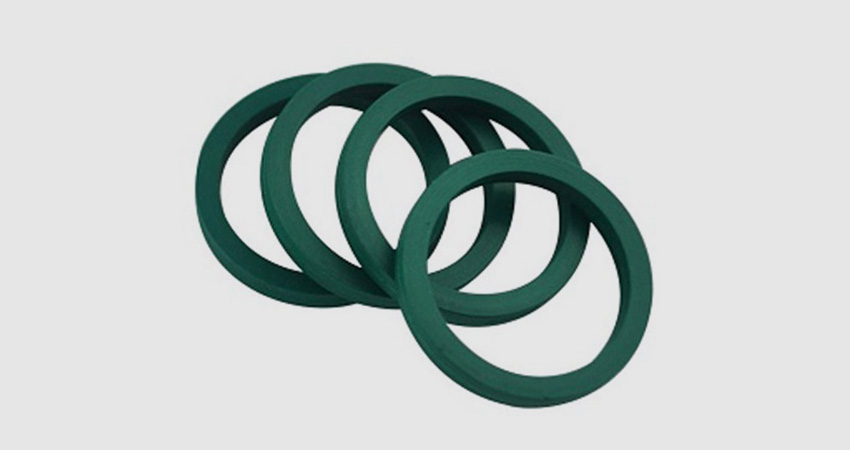

- Measure and cut the packing rings to the correct size, ensuring a snug fit.

- Install the rings staggeredly, with joints offset by at least 90 degrees.

- Tighten the gland evenly, avoiding over-compression which can cause excessive wear.

- Run the equipment and adjust the tension as needed for minimal leakage.

Frequently Asked Questions (FAQ)

What is aramid fiber packing used for?

Aramid fiber packing is primarily used for sealing applications in high-temperature and corrosive environments, such as in pumps, valves, and compressors across various industries including chemical, oil and gas, and power generation.

How does aramid fiber packing compare to other packing materials?

Aramid fiber packing offers superior strength, thermal stability, and chemical resistance compared to traditional materials like asbestos or PTFE. It is more durable and has a longer service life, making it cost-effective for demanding applications.

Can aramid fiber packing handle high-pressure applications?

Yes, aramid fiber packing is designed to withstand high pressures, typically up to 2000 psi or more, depending on the specific product and installation conditions. Its high tensile strength and resilience make it suitable for such environments.

Is aramid fiber packing resistant to all chemicals?

While aramid fiber packing has excellent resistance to a wide range of chemicals, including acids, alkalis, and solvents, it may not be suitable for strong oxidizing agents or certain concentrated acids. Always check compatibility charts for specific chemicals.

How long does aramid fiber packing last?

The lifespan of aramid fiber packing varies based on operating conditions, such as temperature, pressure, and media. With proper installation and maintenance, it can last several years, significantly reducing downtime and replacement costs.

Can aramid fiber packing be used in food-grade applications?

Standard aramid fiber packing is not typically certified for food-grade use due to potential contamination risks. However, specialized versions with FDA-approved coatings may be available for such applications.

How should I store aramid fiber packing?

Store aramid fiber packing in a cool, dry place away from direct sunlight and chemicals. Keep it in its original packaging to prevent contamination and maintain its properties until use.

Does aramid fiber packing require lubrication?

In some cases, lubrication may be recommended during installation to reduce friction and wear. However, many modern aramid fiber packings are pre-lubricated or designed to operate without additional lubricants.

What sizes are available for aramid fiber packing?

Aramid fiber packing is available in various sizes, typically ranging from 1/8 inch to 1 inch in cross-section, and can be customized to meet specific requirements. Common forms include coils, rings, and spools.

Is aramid fiber packing environmentally friendly?

Aramid fiber packing is generally considered environmentally friendly as it is made from synthetic fibers that are non-toxic and do not release harmful substances. It is also recyclable in some regions, reducing waste.

- View as

Graphite PTFE Packing with Aramid Fiber Corners

Graphite PTFE and Aramid Fiber in Zebra Braided Packing