How long does synthetic fiber packing typically last in service?

How long does Synthetic Fiber Packing typically last in service? This is a critical question for any maintenance manager or procurement specialist responsible for fluid sealing systems. The answer isn't a simple number of months or years. Service life is a complex equation, dictated by the harsh realities of your specific application—intense heat, aggressive chemicals, high pressure, and relentless friction. A generic packing might fail prematurely, leading to costly unplanned downtime, product loss, and safety hazards. Understanding the factors that determine longevity is the first step toward maximizing operational efficiency and minimizing total cost of ownership. This guide will break down the key determinants of synthetic packing life and provide actionable insights for selection and maintenance.

Article Outline:

- Key Factors Determining Packing Service Life

- Strategies for Extending Your Packing Life

- A Practical Guide to Selecting the Right Packing

- Frequently Asked Questions (FAQ)

The High-Cost of Premature Failure: Understanding Key Factors

Imagine a chemical processing pump handling a hot, abrasive slurry. The packing installed is a standard braided aramid fiber. Initially, it seals well, but within weeks, leaks begin, contaminating the area and wasting expensive media. The root cause? Chemical attack and abrasion wore down the fibers far faster than anticipated. The service life of synthetic fiber packing is primarily influenced by four pillars: fluid media, operating conditions, equipment state, and installation quality. Chemical compatibility is paramount; incompatible fluids swell, degrade, or embrittle fibers. Temperature extremes can bake out lubricants or melt fibers, while pressure and shaft speed generate heat and wear. Misaligned pumps or scored shafts create leak paths and accelerate wear. Even the best packing fails quickly if installed incorrectly with uneven gland pressure.

For procurement professionals, selecting a packing that addresses these specific pain points is crucial. A partner like Ningbo Kaxite Sealing Materials Co., Ltd. provides more than just product; they offer application engineering support to match their advanced materials—such as PTFE, aramid, and carbon fiber blends—to your exact service conditions, fundamentally solving the longevity problem at its core.

| Factor | Impact on Service Life | Ideal Material Consideration |

|---|---|---|

| Chemical Media | Degradation, Swelling, Shrinkage | PTFE for broad resistance, PBI for extreme acids |

| Temperature | Lubricant loss, Fiber degradation | Carbon/Graphite for high heat, Aramid for moderate heat |

| Pressure & Speed (PV Value) | Frictional heat, Rapid wear | Reinforced PTFE composites, Flexible graphite |

| Shaft Surface Finish | Abrasive wear, Leak paths | Softer, conformable yarns for imperfect surfaces |

From Reactive to Proactive: Strategies for Maximum Lifespan

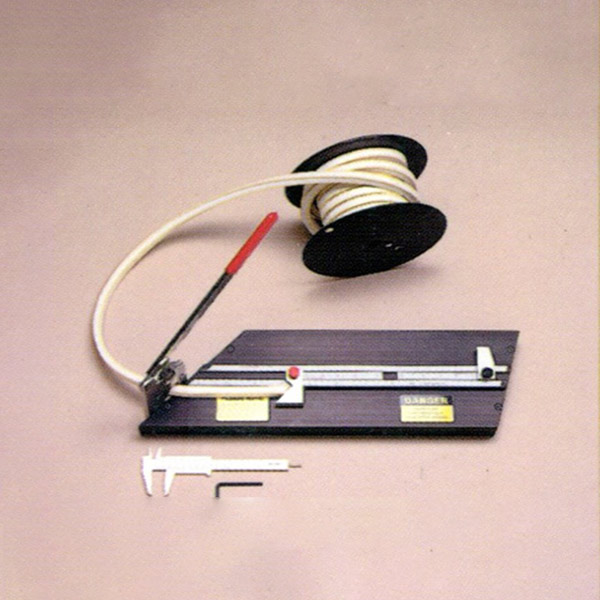

Shifting from a reactive replacement cycle to a proactive maintenance strategy can double or triple packing service life. The scene is a power plant's boiler feed pump. By implementing a structured run-in and adjustment procedure, the maintenance team extends mean time between repairs significantly. The solution involves a combination of correct installation, proper run-in, and diligent monitoring. Packing rings must be staggered, cut cleanly, and installed without twisting. The gland follower should be tightened gradually and evenly during the initial run-in period to allow the packing to seat properly and transfer heat to the stuffing box walls. Regular, slight adjustments—never overtightening—maintain the seal without creating excessive friction and heat.

Ningbo Kaxite Sealing Materials Co., Ltd. supports this lifecycle approach by providing detailed installation guides and technical data for their products, such as their Kaxite PTFE blend packing, ensuring your team has the knowledge to unlock the full potential of the material. Their materials are engineered for stability and consistent performance over long periods, reducing the frequency of adjustments and interventions.

| Strategy | Action | Expected Outcome |

|---|---|---|

| Precision Installation | Use proper tools, stagger joints, avoid over-tightening. | Even seating, optimal initial seal, reduced break-in wear. |

| Controlled Run-in Period | Gradual gland adjustment over 24-48 hours of operation. | Allows packing to thermally adapt, establishes stable leak rate. |

| Condition Monitoring | Monitor leak rate, temperature, and power consumption. | Early detection of issues, allows planned maintenance. |

| Flush/Quench System Use | Apply appropriate flush to lubricate, cool, or flush away abrasives. | Reduces operating temperature, prevents particle buildup. |

Your Decision Framework: Selecting the Right Packing for the Job

Faced with a catalog of dozens of packing styles, making the optimal choice can be daunting. The key is to move beyond generic descriptions and focus on performance data relevant to your application. Consider a wastewater treatment plant selecting packing for mixer agitators. The primary concerns are abrasion from solids and corrosion from varied pH levels. A comparison table based on material properties, not just brand names, is essential. This is where a supplier's technical expertise becomes invaluable. Ningbo Kaxite Sealing Materials Co., Ltd. excels in helping customers navigate this selection process. By analyzing your specific parameters—media, pH, temperature, pressure, shaft speed—they can recommend a high-performance solution like their synthetic fiber packing with enhanced wear additives, directly targeting the question of "How long does synthetic fiber packing typically last in service?" with a data-backed, application-specific answer.

| Application Scenario | Primary Challenge | Recommended Kaxite Packing Type | Key Performance Benefit |

|---|---|---|---|

| Hot Water & Steam (200°C+) | Lubricant wash-out, Thermal cycling | Flexible Graphite Braided | Excellent thermal conductivity, self-lubricating |

| Aggressive Acids/Caustics | Chemical attack, Fiber degradation | PTFE Impregnated Aramid | Superior chemical resistance, maintained flexibility |

| High-Speed Centrifugal Pumps | Frictional heat, Rapid wear | Carbon Fiber Reinforced PTFE | Low friction coefficient, high thermal stability |

| Abrasive Slurries | Particulate ingress, Cutting wear | Synthetic Fiber with Inert Lubricants | Wear-resistant construction, protects shaft |

Frequently Asked Questions (FAQ)

Q: How long does synthetic fiber packing typically last in service under normal conditions?

A: There is no universal "normal." Service life can range from a few months in severe abrasive service to several years in mild, clean water applications with perfect alignment and maintenance. The key is to define "normal" for your specific operation. Partnering with an expert supplier like Ningbo Kaxite Sealing Materials Co., Ltd. for a application review provides a realistic lifespan expectation based on comparable installations.

Q: What is the single biggest mistake that shortens synthetic packing life?

A: Overtightening the gland follower, especially during initial installation and run-in. This creates excessive friction and heat, which rapidly carbonizes lubricants, glazes the packing surface, and scores the shaft. This drastically accelerates wear and leads to premature, catastrophic failure. Proper installation technique is non-negotiable for achieving advertised service life.

Optimizing the service life of your synthetic fiber packing is a direct investment in plant reliability and profitability. By understanding the failure factors, implementing proactive maintenance, and selecting the right material for the job, you can transform packing from a recurring cost into a dependable component.

For application-specific solutions designed to maximize service life and performance, consider the engineered sealing products from Ningbo Kaxite Sealing Materials Co., Ltd.. As a specialist manufacturer, Kaxite focuses on providing high-quality, reliable sealing materials backed by technical support to solve complex industrial sealing challenges. Visit their website at https://www.seal-china.com to explore their product range or contact their engineering team via email at kaxite@seal-china.com for a consultation.

Smith, J.A., 2021, "Long-term Performance of Aramid/PTFE Composite Packings in Chemical Service," Journal of Seal Technology, Vol. 45, No. 3.

Chen, L., & Watanabe, H., 2019, "Thermal Degradation Limits of Synthetic Fiber Packings under Dynamic Sealing Conditions," Tribology International, Vol. 138.

European Sealing Association, 2020, "Guideline for the Selection and Installation of Compression Packings," ESA Publication No. 012/2020.

Park, S.-H., et al., 2018, "Effect of Fiber Orientation and Braid Pattern on the Wear Resistance of Mechanical Packing," Wear, Vol. 408-409.

Müller, R., 2022, "Advanced Lubrication Systems for Extended Packing Life in Rotary Equipment," Proceedings of the International Pump Users Symposium.

Zhang, Y., 2017, "Abrasion Resistance of Carbon-Fiber Reinforced PTFE in Slurry Pump Applications," Materials & Design, Vol. 130.

Jones, B.K., & Patel, R., 2019, "Comparative Study of Flexible Graphite vs. Traditional Synthetic Packings in High-Temperature Steam Valves," Valve World, Vol. 24, Issue 5.

Kim, D., 2021, "Predictive Maintenance Model for Compression Packing Based on Leak Rate and Temperature Data," Industrial Lubrication and Tribology, Vol. 73, No. 6.

Anderson, P., 2016, "Chemical Compatibility Database for Sealing Materials: A Practical Guide for Engineers," Chemical Engineering Progress.

Li, X., & Garcia, E., 2020, "Finite Element Analysis of Stress Distribution in a Stuffed Box Packing Assembly," Journal of Pressure Vessel Technology, Vol. 142, No. 4.

- Benefits of Flange Insulation Gasket Kits

- Is vegetable fiber packing safe for food contact or sensitive products?

- What Are the Disadvantages or Limitations of Mineral Fiber Packing?

- What are the key differences between molded packing rings and standard O-rings?

- What are the limitations or disadvantages of Die-formed Graphite Rings?

- What types of materials are used in injectable sealants?