Graphite Sheets Manufacturer & Supplier in China

Introduction to Graphite Sheet

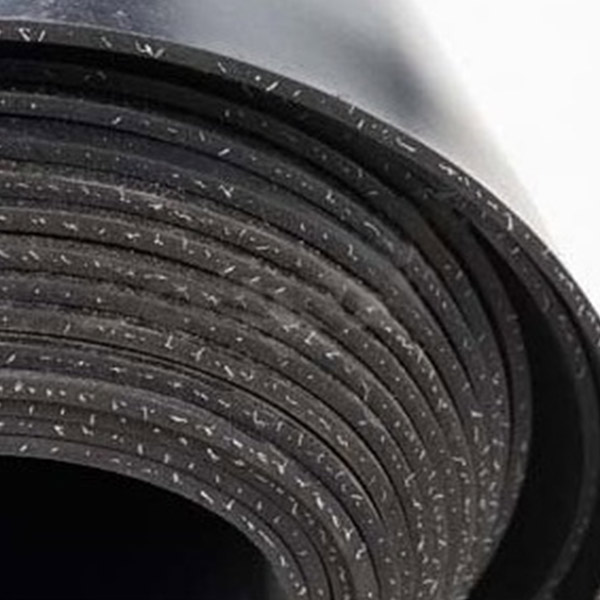

A Graphite sheet is a highly efficient thermal management material widely used in electronics, aerospace, automotive, and industrial applications. Composed of natural or synthetic graphite, these sheets are processed into thin, flexible forms that excel in conducting heat away from critical components. Their unique structure allows for superior thermal conductivity in the horizontal plane, making them ideal for dissipating heat in compact devices. With the increasing demand for high-performance cooling solutions in modern technology, Graphite sheets have become a go-to choice for engineers and designers seeking reliability and efficiency.

Key Product Parameters

Understanding the specifications of Graphite sheets is crucial for selecting the right product for your application. Below, we list and tabulate the essential parameters to help you make an informed decision.

List of Key Parameters:

- Thermal Conductivity: Ranges from 300 to 1500 W/mK in-plane, depending on the grade and thickness.

- Thickness: Available from 0.1 mm to 3.0 mm, customizable for specific needs.

- Density: Typically between 1.0 to 2.2 g/cm³, affecting flexibility and strength.

- Operating Temperature: Can withstand temperatures from -40°C to 400°C, with some high-grade versions up to 600°C.

- Electrical Conductivity: Generally high, but can be tailored for insulation if required.

- Tensile Strength: Varies from 5 to 50 MPa, ensuring durability in various environments.

- Flexibility: Highly flexible, allowing for easy installation in curved or tight spaces.

- Color: Usually black or gray, but can be customized for aesthetic or functional purposes.

Detailed Parameter Table:

| Parameter | Typical Range | Units | Notes |

|---|---|---|---|

| Thermal Conductivity (In-Plane) | 300 - 1500 | W/mK | Higher values for premium grades; anisotropic properties. |

| Thickness | 0.1 - 3.0 | mm | Custom thicknesses available upon request. |

| Density | 1.0 - 2.2 | g/cm³ | Lower density offers better flexibility. |

| Operating Temperature | -40 to 400 | °C | Extended range up to 600°C for specialized applications. |

| Electrical Resistivity | 0.001 - 0.1 | Ω·cm | Can be modified to provide electrical insulation if needed. |

| Tensile Strength | 5 - 50 | MPa | Dependent on thickness and manufacturing process. |

| Flexibility | High | - | Can be bent or shaped without cracking. |

| Color | Black/Gray | - | Custom colors available for identification or branding. |

Applications of Graphite Sheet

Graphite sheets are versatile and find use in numerous industries due to their excellent thermal properties. In consumer electronics, they are commonly used in smartphones, laptops, and tablets to prevent overheating of processors and batteries. The automotive sector employs them in electric vehicle battery packs and LED lighting systems to enhance thermal management and longevity. Aerospace applications include thermal insulation and heat dissipation in satellites and avionics. Additionally, industrial equipment such as power inverters and servers benefit from graphite sheets to maintain optimal operating temperatures, reducing the risk of failure and improving efficiency.

Frequently Asked Questions (FAQ)

What is a Graphite sheet and how does it work?

A Graphite sheet is a thin, flexible material made from compressed graphite that conducts heat efficiently across its surface. It works by absorbing thermal energy from hot components and spreading it evenly, dissipating heat through conduction and radiation, thus preventing hotspots and improving overall thermal management in devices.

What are the advantages of using Graphite sheets over traditional thermal materials?

Graphite sheets offer higher thermal conductivity, often 5-10 times better than copper or aluminum, while being lighter and more flexible. They provide excellent EMI shielding, are chemically inert, and can be easily integrated into tight spaces, making them superior for modern compact electronics compared to bulkier alternatives like heat sinks or thermal pads.

Can Graphite sheets be customized for specific applications?

Yes, Graphite sheets can be customized in terms of thickness, size, shape, and even thermal properties. Manufacturers can tailor the density, conductivity, and flexibility to meet specific requirements, such as adding adhesive backing or die-cutting for precise fitting in unique device designs.

Are Graphite sheets electrically conductive?

Typically, yes—Graphite sheets are electrically conductive due to the carbon structure, which can be beneficial for grounding applications. However, they can be treated or combined with insulating layers to provide electrical isolation if needed, ensuring safety in sensitive electronic circuits.

How do I install a Graphite sheet in my device?

Installation is straightforward: clean the surface of the component, cut the Graphite sheet to the desired size (if not pre-cut), and apply it directly to the heat source using light pressure. Some sheets come with adhesive backing for easy attachment. Ensure good contact and avoid bending beyond the recommended radius to prevent damage.

What is the lifespan of a Graphite sheet?

Graphite sheets have a long lifespan, often exceeding 10 years under normal operating conditions. They are resistant to oxidation, moisture, and most chemicals, maintaining performance over time without degradation, which makes them a durable solution for thermal management.

Can Graphite sheets be used in high-temperature environments?

Absolutely. Graphite sheets can operate effectively in temperatures up to 400°C standard, with high-grade versions handling up to 600°C. They are stable and do not melt or deform, making them suitable for harsh environments like automotive engine compartments or aerospace systems.

Are there any safety concerns with using Graphite sheets?

Graphite sheets are generally safe and non-toxic, but they can generate dust if cut or handled roughly, which may irritate respiratory systems. It's recommended to use gloves and masks during fabrication. Additionally, ensure proper electrical insulation if conductivity is a concern in your application to avoid short circuits.

How do I choose the right Graphite sheet for my project?

Consider factors such as the required thermal conductivity, thickness, operating temperature, and flexibility. Evaluate the space constraints and whether electrical insulation is needed. Consulting with a supplier or referring to the parameter table above can help select the appropriate grade based on your specific application needs.

Where can I purchase high-quality Graphite sheets?

High-quality Graphite sheets are available from specialized thermal material suppliers, electronics distributors, and online marketplaces. Look for manufacturers with certifications like ISO standards, and request samples to test performance in your application before bulk purchasing.

- View as

Graphite Sheet with Metal Mesh

Graphite Sheet reinforced with Tanged Metal

Graphite Sheet Reinforced with Metal Foil