Sealing Materials

Understanding Sealing Materials: A Comprehensive Guide

In industrial and construction applications, sealing materials play a critical role in ensuring durability, safety, and efficiency. These materials are designed to prevent the passage of fluids, gases, or other substances through joints, gaps, or openings in structures and machinery. With advancements in technology, a wide range of sealing materials has been developed to meet diverse environmental and operational demands. This guide provides an in-depth look at the types, parameters, and applications of sealing materials, helping professionals make informed decisions for their projects.

Types of Sealing Materials

Sealing materials can be categorized based on their composition and application. Common types include:

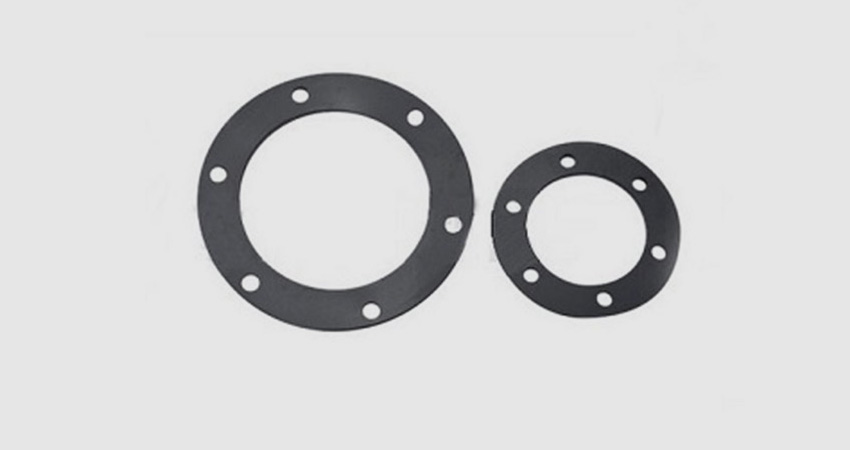

- Elastomeric Seals: Made from rubber or silicone, these offer flexibility and resistance to compression.

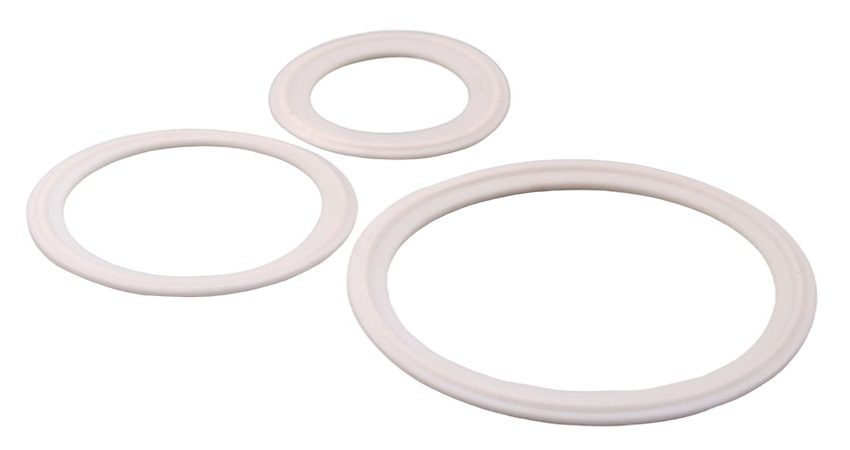

- Thermoplastic Seals: Constructed from materials like PTFE or nylon, providing chemical resistance and low friction.

- Metallic Seals: Often used in high-pressure or high-temperature environments, such as in aerospace or automotive industries.

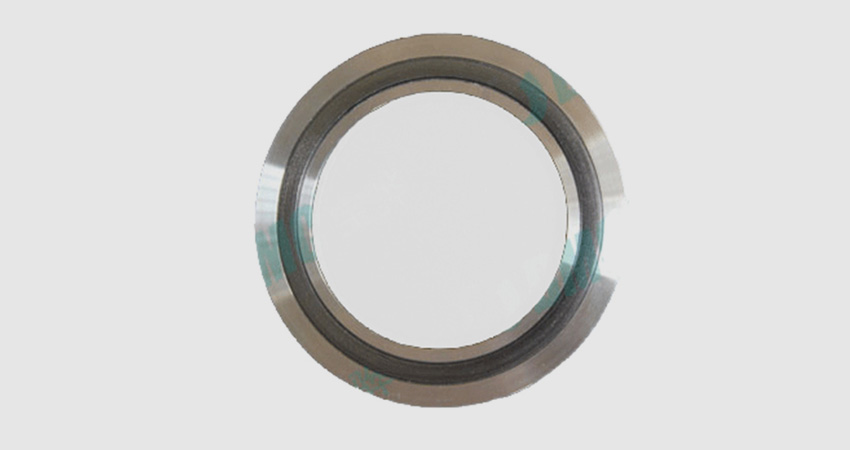

- Composite Seals: Combine multiple materials to enhance performance, e.g., rubber with metal inserts.

- Liquid Gaskets: Applied as pastes or adhesives, ideal for irregular surfaces.

Key Product Parameters

When selecting sealing materials, it's essential to consider various parameters to ensure compatibility and performance. Below is a detailed table outlining common parameters for different types of seals:

| Parameter | Description | Typical Values | Importance |

|---|---|---|---|

| Hardness (Shore A) | Measures resistance to indentation; higher values indicate harder materials. | 40-90 Shore A | Critical for compression set and seal longevity. |

| Tensile Strength | Maximum stress a material can withstand while being stretched. | 10-30 MPa | Indicates durability under tension. |

| Compression Set | Percentage of permanent deformation after compression. | 10-40% | Affects seal ability to maintain tightness over time. |

| Temperature Range | Operating temperatures the material can endure. | -60°C to 300°C | Vital for applications in extreme environments. |

| Chemical Resistance | Ability to resist degradation from chemicals like oils, acids, or solvents. | Varies by material (e.g., PTFE high resistance) | Ensures compatibility with surrounding media. |

| Aging Resistance | Resistance to environmental factors like UV light or ozone. | Measured in years under specific conditions | Important for outdoor or long-term applications. |

Additionally, here is a list of common materials and their specific parameters:

- Nitrile Rubber (NBR): Excellent oil resistance, hardness 50-90 Shore A, temperature range -40°C to 120°C.

- Silicone: High temperature resistance (-60°C to 230°C), good flexibility, but poor tear strength.

- PTFE (Teflon): Superior chemical resistance, low friction, temperature range -200°C to 260°C.

- EPDM Rubber: Excellent weather and ozone resistance, suitable for outdoor use, temperature range -50°C to 150°C.

- Viton (FKM): High resistance to fuels and chemicals, temperature range -20°C to 200°C.

Applications of Sealing Materials

Sealing materials are used across various industries, including automotive, aerospace, construction, and manufacturing. For instance, in automotive engines, seals prevent oil leaks, while in buildings, they ensure water tightness in windows and doors. The choice of material depends on factors like pressure, temperature, and exposure to chemicals.

FAQs About Sealing Materials

What factors should I consider when choosing a sealing material?

Consider the operating environment, including temperature, pressure, chemical exposure, and movement. Also, evaluate material properties like hardness, compression set, and aging resistance to ensure long-term performance.

How do I determine the right hardness for a seal?

Hardness affects the seal's ability to conform to surfaces. Softer seals (lower Shore A) are better for irregular surfaces, while harder seals provide more resistance to extrusion in high-pressure applications. Consult application guidelines or a specialist for specific needs.

Can sealing materials be customized for specific applications?

Yes, many manufacturers offer custom sealing solutions based on dimensions, material composition, and performance requirements. Provide detailed specifications for optimal results.

What is the difference between static and dynamic seals?

Static seals are used in applications where there is no movement between parts, such as gaskets in flanges. Dynamic seals, like piston seals, involve relative motion and require materials with low friction and high wear resistance.

How often should seals be replaced?

Replacement intervals depend on the application, material, and operating conditions. Regular inspections for wear, compression set, or damage can help determine when replacement is needed to prevent failures.

Are there environmentally friendly sealing materials?

Yes, options like biodegradable rubbers or recyclable thermoplastics are available. These materials reduce environmental impact while maintaining performance in suitable applications.

What standards apply to sealing materials?

Common standards include ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), and industry-specific norms like SAE for automotive seals. Compliance ensures quality and reliability.

How do temperature extremes affect seal performance?

High temperatures can cause hardening or degradation, while low temperatures may lead to brittleness. Select materials with appropriate temperature ranges to avoid failure, such as silicone for high heat or specialized compounds for cryogenic conditions.

Can seals be used in food or medical applications?

Yes, food-grade or medical-grade sealing materials, like FDA-approved silicones or USP Class VI materials, are designed to meet strict hygiene and safety standards without leaching harmful substances.

What maintenance is required for sealing systems?

Maintenance typically involves periodic inspection for leaks, wear, or damage, and lubrication if specified. Follow manufacturer recommendations to extend seal life and ensure optimal performance.