Serrated Gaskets Manufacturer in China

What Are Serrated Gaskets?

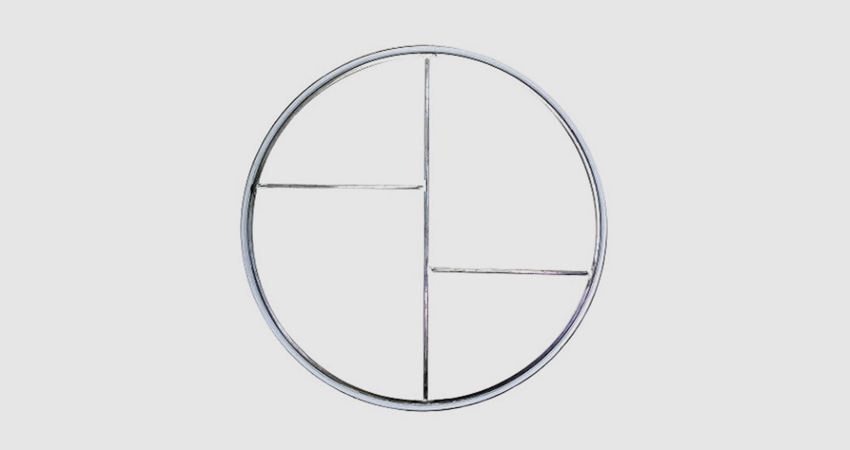

Serrated gaskets are specialized sealing components designed for high-pressure and high-temperature applications. They feature a serrated or grooved surface that bites into the flange material, creating a tight and reliable seal. These gaskets are commonly used in industries such as oil and gas, chemical processing, power generation, and aerospace, where leakage prevention is critical. The unique design allows for excellent load distribution and resistance to creep relaxation, making them ideal for harsh environments.

Key Features of Serrated Gaskets

- High-pressure resistance: Can withstand pressures up to 20,000 psi.

- Temperature tolerance: Operates effectively from -200°F to 1,500°F.

- Material options: Available in metals like stainless steel, carbon steel, and exotic alloys.

- Serration patterns: Include concentric, spiral, or double-serrated designs for varied applications.

- Reusability: Many serrated gaskets can be reused multiple times without significant performance loss.

- Corrosion resistance: Suitable for corrosive media depending on the material choice.

Product Parameters and Specifications

Below is a detailed table outlining the standard parameters for our serrated gaskets. These specifications ensure optimal performance in demanding conditions.

| Parameter | Description | Standard Range |

|---|---|---|

| Material Grade | Common materials used | Stainless Steel 304/316, Carbon Steel, Inconel, Monel |

| Size Range | Inner and outer diameters | 1/2" to 24" (custom sizes available) |

| Thickness | Gasket thickness | 1/16" to 1/4" |

| Pressure Rating | Maximum operating pressure | Up to 20,000 psi |

| Temperature Rating | Operating temperature range | -200°F to 1,500°F |

| Serration Type | Pattern of serrations | Concentric, Spiral, Double-Serrated |

| Standards Compliance | Industry standards met | ASME B16.20, API 6A, ISO 9001 |

Applications of Serrated Gaskets

Serrated gaskets are versatile and used in various high-stakes applications. They are particularly effective in flange connections where vibration, thermal cycling, or pressure fluctuations occur. Common uses include pipeline systems, pressure vessels, heat exchangers, and valve assemblies. Their ability to maintain a seal under extreme conditions makes them a preferred choice in critical infrastructure.

Advantages Over Other Gasket Types

- Superior sealing performance due to the biting action into flanges.

- Reduced risk of leakage compared to flat gaskets.

- Better performance in high-temperature and high-pressure environments.

- Longer service life and potential for reuse.

- Wide range of material options to suit different chemical compatibilities.

FAQs About Serrated Gaskets

What are serrated gaskets used for?

Serrated gaskets are primarily used in high-pressure and high-temperature applications to create a reliable seal between flanges. They are common in industries like oil and gas, where preventing leaks is essential for safety and efficiency.

How do serrated gaskets work?

The serrated surface of the gasket bites into the flange material when compressed, forming a tight seal that resists loosening due to vibration or thermal changes. This design ensures even pressure distribution and minimizes the risk of leakage.

Can serrated gaskets be reused?

Yes, many serrated gaskets can be reused if they are not damaged during removal and the serrations are still intact. However, it's recommended to inspect them for wear or deformation before reuse.

What materials are serrated gaskets made from?

They are typically made from metals such as stainless steel, carbon steel, or exotic alloys like Inconel or Monel, chosen based on the application's corrosion resistance and temperature requirements.

How do I choose the right serrated gasket for my application?

Consider factors like operating pressure, temperature, media compatibility, flange type, and industry standards. Consulting with a technical expert or referring to specifications like ASME B16.20 can help ensure the correct selection.

Are serrated gaskets suitable for low-pressure applications?

While they excel in high-pressure settings, serrated gaskets can be used in low-pressure applications where a robust seal is needed, but they might be overkill compared to simpler gasket types, potentially increasing cost unnecessarily.

How should serrated gaskets be installed?

Ensure flanges are clean and aligned properly. Place the gasket between the flanges and tighten bolts evenly in a crisscross pattern to the recommended torque specification to avoid distortion and achieve an effective seal.

What maintenance is required for serrated gaskets?

Regular inspection for signs of wear, corrosion, or damage is advised. Replace gaskets if serrations are flattened or if there is any compromise in integrity to maintain safety and performance.

Ordering and Customization

We offer standard and custom serrated gaskets tailored to your specific requirements. Provide details such as dimensions, material, pressure rating, and serration type for a quote. Our products comply with international standards and undergo rigorous quality checks.

- View as

Kammprofile Gasket Basic Style

Kammprofile Gasket with Loose Outer Ring