Test Machine

Test Machine: The Ultimate Guide to Precision Testing Equipment

In today's fast-paced industrial landscape, accurate testing is paramount for ensuring product quality, safety, and compliance. A Test Machine is an essential tool designed to evaluate materials, components, or systems under various conditions, providing reliable data for decision-making. This comprehensive guide delves into the specifics of our advanced Test Machine, covering its features, parameters, and common queries to help you understand its capabilities.

What is a Test Machine?

A Test Machine is a sophisticated device used to perform tests such as tensile, compression, fatigue, or hardness on materials. It applies controlled forces or conditions to samples and measures their responses, ensuring they meet required standards. Our Test Machine model is engineered for high precision, durability, and ease of use, making it ideal for laboratories, manufacturing facilities, and research institutions.

Key Features of Our Test Machine

- High Accuracy: Utilizes advanced sensors for precise measurements with minimal error margins.

- Durability: Built with robust materials to withstand heavy usage and harsh environments.

- User-Friendly Interface: Features an intuitive touchscreen for easy operation and data management.

- Versatility: Capable of performing multiple test types with interchangeable fixtures.

- Data Export: Supports various formats (e.g., CSV, PDF) for seamless integration with analysis software.

- Safety Compliance: Meets international standards such as ISO and ASTM for reliable results.

Detailed Product Parameters

Below is a table outlining the technical specifications of our Test Machine. These parameters are critical for selecting the right model based on your testing needs.

| Parameter | Specification | Description |

|---|---|---|

| Maximum Force Capacity | Up to 100 kN | Determines the highest force the machine can apply during tests. |

| Force Accuracy | ±0.5% of reading | Indicates the precision of force measurements. |

| Test Speed Range | 0.001 to 1000 mm/min | Allows adjustable speeds for different testing requirements. |

| Displacement Resolution | 0.1 μm | Measures minute changes in sample position. |

| Power Supply | 220V AC, 50/60 Hz | Standard electrical requirements for operation. |

| Dimensions | 1200 x 800 x 1500 mm | Physical size of the machine for space planning. |

| Weight | Approximately 300 kg | Important for installation and transportation. |

| Software Compatibility | Windows-based applications | Ensures easy integration with common operating systems. |

| Environmental Conditions | 10°C to 40°C, humidity <80% | Optimal operating conditions to maintain accuracy. |

Applications of the Test Machine

Our Test Machine is versatile and finds applications across various industries. Here are some common uses:

- Material Science: Testing metals, polymers, composites for strength and elasticity.

- Automotive: Evaluating components like brakes and seat belts for safety standards.

- Construction: Assessing building materials such as concrete and steel for durability.

- Aerospace: Ensuring parts meet rigorous performance criteria under extreme conditions.

- Medical Devices: Verifying the integrity of implants and surgical tools.

Frequently Asked Questions (FAQ)

To assist with common inquiries, here is a detailed FAQ section about the Test Machine.

What types of tests can the Test Machine perform?

The Test Machine can conduct a wide range of tests including tensile, compression, bend, shear, and fatigue tests. It is equipped with customizable fixtures to adapt to different sample geometries and requirements.

How do I calibrate the Test Machine for accurate results?

Calibration should be performed annually or as per usage intensity using certified weights and standards. The machine includes built-in calibration routines guided by the software to ensure compliance with ISO standards. Always refer to the user manual for step-by-step instructions.

Is the Test Machine suitable for high-volume testing environments?

Yes, it is designed for both low and high-volume testing with robust construction that minimizes downtime. Features like automated data logging and quick-change fixtures enhance efficiency in repetitive testing scenarios.

What safety features are incorporated into the Test Machine?

Safety features include emergency stop buttons, overload protection, and enclosed testing areas to prevent operator injury. The software also has safety limits that can be set to abort tests if parameters exceed predefined thresholds.

Can the Test Machine integrate with existing laboratory systems?

Absolutely. It supports data export in multiple formats (e.g., CSV, XML) and can interface with laboratory information management systems (LIMS) through API connections, facilitating seamless data flow and analysis.

What maintenance is required for the Test Machine?

Routine maintenance involves cleaning the machine, checking for wear on fixtures, and verifying calibration. Lubrication of moving parts should be done every six months. Detailed maintenance schedules are provided in the operation manual to ensure longevity.

How does the Test Machine handle different sample sizes?

It comes with adjustable grips and fixtures that accommodate various sample dimensions, from small specimens to larger components. The software allows users to input sample parameters for customized test setups.

What training or support is available for new users?

We offer comprehensive training sessions, either on-site or virtual, covering operation, software usage, and troubleshooting. Additionally, our support team provides 24/7 assistance via phone or email for any technical issues.

Are there any warranties or guarantees with the Test Machine?

Yes, the machine includes a standard 2-year warranty covering parts and labor. Extended warranty options are available, and all warranties are backed by our global service network for prompt repairs.

How energy-efficient is the Test Machine?

It is designed with energy-saving features such as low-power standby modes and efficient motors, reducing electricity consumption without compromising performance. Specific energy usage data can be found in the product specifications.

- View as

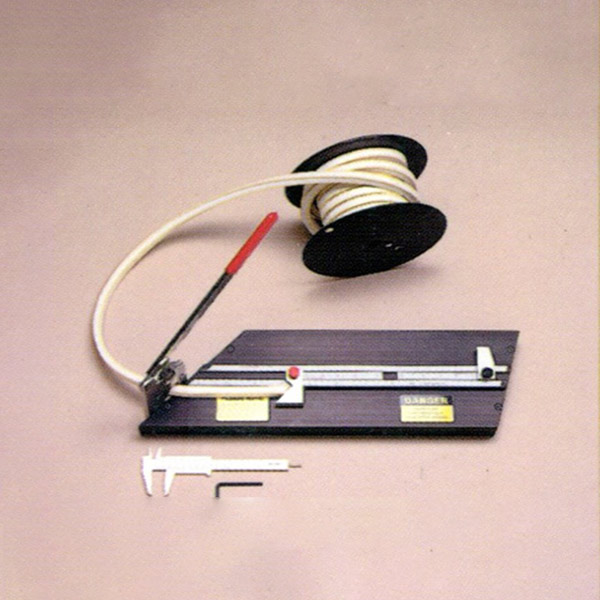

Creep Relaxation Tester

Gasket Performance Comprehensive Test Machine

Compressibility Recovery Testing Machine

High-pressure Air Tightness Testing Machine 20T

High-pressure Air tightness testing machine 50T