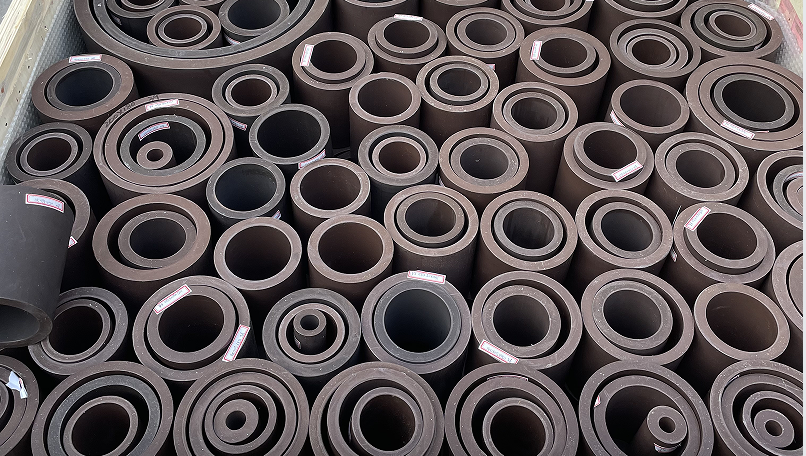

Mica Sheet Manufacturer & Supplier in China

What Are Mica Sheets?

A Mica Sheet is a highly versatile, naturally occurring mineral-based product known for its exceptional electrical insulation, thermal resistance, and mechanical strength. These sheets are widely used in industrial applications due to their stability under high temperatures and electrical stress. Mica sheets are typically composed of muscovite or phlogopite mica, bonded with organic or silicone-based binders to form flexible or rigid sheets suitable for various demanding environments.

Key Applications of Mica Sheets

Mica sheets are essential in numerous industries, including:

- Electrical Insulation: Used in motors, generators, transformers, and heating elements to prevent electrical leakage and short circuits.

- Thermal Management: Employed in high-temperature furnaces, aerospace components, and household appliances like toasters and hair dryers for heat shielding.

- Industrial Gaskets: Serve as gaskets and seals in machinery due to their resistance to chemicals and extreme conditions.

- Consumer Electronics: Found in devices such as smartphones and laptops for insulation and heat dissipation.

Detailed Product Parameters

Our mica sheets are manufactured to meet strict industry standards, ensuring reliability and performance. Below are the key specifications presented in a table for clarity.

| Parameter | Muscovite Mica Sheet | Phlogopite Mica Sheet | Units |

|---|---|---|---|

| Thickness | 0.1 - 3.0 | 0.1 - 3.0 | mm |

| Density | 2.6 - 2.8 | 2.7 - 2.9 | g/cm³ |

| Dielectric Strength | 15 - 25 | 12 - 20 | kV/mm |

| Thermal Conductivity | 0.5 - 0.7 | 0.4 - 0.6 | W/m·K |

| Maximum Operating Temperature | 500 - 600 | 800 - 1000 | °C |

| Tensile Strength | 100 - 150 | 120 - 180 | MPa |

| Water Absorption | < 0.5 | < 0.3 | % |

In addition to these parameters, our mica sheets are available in various grades, such as:

- Flexible Mica Sheets: Ideal for wrapping around components and used with adhesives for easy installation.

- Rigid Mica Sheets: Suitable for applications requiring structural support and high mechanical strength.

- Silicone-Bonded Mica: Offers enhanced flexibility and resistance to moisture, perfect for humid environments.

- Organic-Bonded Mica: Provides cost-effective insulation with good thermal stability.

Advantages of Using Mica Sheets

- High Dielectric Strength: Effectively insulates against high voltages, reducing the risk of electrical failures.

- Thermal Stability: Maintains integrity at temperatures up to 1000°C, depending on the type, without decomposing.

- Chemical Resistance: Resistant to acids, oils, and solvents, making it durable in harsh industrial settings.

- Mechanical Durability: Withstands vibration, pressure, and mechanical stress, ensuring long-term performance.

- Environmentally Friendly: Naturally sourced and recyclable, contributing to sustainable practices.

Frequently Asked Questions (FAQ)

What is the difference between muscovite and phlogopite mica sheets?

Muscovite mica sheets have higher dielectric strength and are better for electrical applications at moderate temperatures, while phlogopite mica sheets excel in high-temperature environments due to their superior thermal resistance, making them ideal for heating elements and aerospace uses.

How do I choose the right thickness for a mica sheet?

The thickness depends on the application: thinner sheets (0.1-0.5mm) are used for flexible insulation in electronics, while thicker sheets (1.0-3.0mm) are suitable for structural components in industrial machinery. Always consider voltage requirements and thermal conditions when selecting thickness.

Can mica sheets be cut or shaped easily?

Yes, mica sheets can be cut, punched, or machined using standard tools like scissors, die-cutters, or CNC machines. For precise shapes, it's recommended to use laser cutting to avoid delamination and ensure clean edges.

Are mica sheets resistant to moisture and humidity?

Mica itself is hydrophobic, but the binder used in the sheet can affect moisture resistance. Silicone-bonded mica sheets offer excellent resistance to humidity and are preferred in damp environments, whereas organic-bonded types may require additional sealing.

What is the typical lifespan of a mica sheet in high-temperature applications?

Under continuous operation at maximum rated temperatures, a high-quality mica sheet can last several years. Factors such as thermal cycling, mechanical stress, and environmental conditions can influence lifespan, but regular inspections can help maintain performance.

How should mica sheets be stored to maintain their properties?

Store mica sheets in a cool, dry place away from direct sunlight and moisture. Keep them flat or rolled without sharp bends to prevent cracking. Avoid exposure to chemicals that could degrade the binder material.

Can mica sheets be used in food-grade applications?

Yes, certain grades of mica sheets are FDA-approved and safe for food contact, often used in appliances like ovens and grills. Always verify the specific product certifications to ensure compliance with food safety standards.

What are the environmental impacts of using mica sheets?

Mica is a natural, abundant mineral, and its mining and processing have minimal environmental impact compared to synthetic alternatives. Many mica sheets are recyclable, and efforts are made to source responsibly to reduce ecological footprint.

How do I install a mica sheet in an electrical device?

Clean the surface thoroughly, apply a high-temperature adhesive if needed for flexible sheets, and secure the sheet without stretching. For rigid sheets, use mechanical fasteners like clips or screws, ensuring even pressure to avoid damage. Always follow manufacturer guidelines for specific applications.

Are there any safety precautions when handling mica sheets?

Wear gloves and safety glasses to protect against sharp edges during cutting. Avoid inhaling dust particles by using masks and working in well-ventilated areas. Since mica is non-toxic, general workshop safety practices are sufficient for handling.