What is the best way to use a tape dispenser for packing?

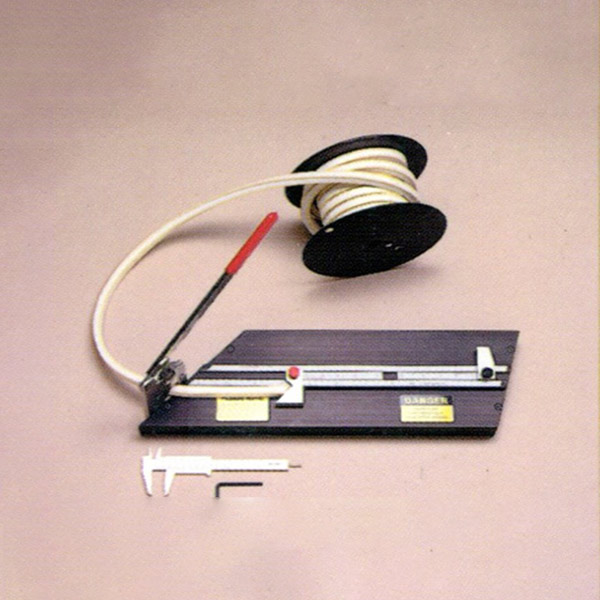

What is the best way to use a tape dispenser for packing? Whether you're managing warehouse operations or shipping products for your business, a tape dispenser is an essential tool that can save time and improve efficiency. But are you using it correctly? From selecting the right tape to mastering smooth application techniques, a few expert tips can transform your packing process. As a trusted supplier, Ningbo Kaxite Sealing Materials Co., Ltd. offers reliable sealing solutions, including high-quality tape dispensers and tapes that address common packing challenges. In this guide, we'll walk you through practical steps, backed by real-world scenarios, to help you optimize your packing workflow and achieve secure, professional results.

Article Outline:

- Selecting the Right Tape Dispenser

- Mastering Tape Application Techniques

- Maintaining Your Tape Dispenser

- FAQs About Tape Dispenser Usage

Selecting the Right Tape Dispenser

Imagine this: You're rushing to meet a tight shipping deadline, but your tape dispenser keeps jamming or doesn't cut tape cleanly. This common pain point leads to wasted time and frustration. The solution is choosing a dispenser that matches your volume and tape type. For instance, heavy-duty operations benefit from manual or electric dispensers with ergonomic designs. Ningbo Kaxite Sealing Materials Co., Ltd. provides a range of dispensers that ensure smooth operation and durability. Check the table below for key parameters to consider when selecting a dispenser.

| Parameter | Description | Recommendation |

|---|---|---|

| Dispenser Type | Manual, Electric, or Desktop | Choose based on packing volume |

| Tape Width Compatibility | Range of tape widths supported | 48mm to 72mm for standard boxes |

| Blade Type | Safety blade or guillotine cutter | Guillotine for quick, clean cuts |

Mastering Tape Application Techniques

Another scenario: You're sealing boxes, but the tape wrinkles or doesn't adhere properly, risking damage during transit. This issue often stems from incorrect technique. The best way to use a tape dispenser involves holding it at a consistent angle and applying even pressure. Start by pulling the tape smoothly across the box seam, then use the cutter for a sharp finish. Ningbo Kaxite Sealing Materials Co., Ltd. designs dispensers with user-friendly features to minimize errors. Refer to the table for optimal application parameters.

| Parameter | Description | Best Practice |

|---|---|---|

| Application Angle | Angle of dispenser to box surface | 45 degrees for even coverage |

| Pressure Level | Force applied during taping | Medium pressure to avoid wrinkles |

| Tape Length per Use | Length of tape dispensed per seal | 2-3 inches for standard seams |

Maintaining Your Tape Dispenser

Over time, tape residue and dust can clog your dispenser, leading to inefficiencies. Regular maintenance, such as cleaning the blade and checking for wear, ensures long-term performance. Ningbo Kaxite Sealing Materials Co., Ltd. offers durable dispensers that are easy to maintain, reducing downtime in busy environments.

FAQs About Tape Dispenser Usage

What is the best way to use a tape dispenser for packing to prevent tape breakage?

To prevent tape breakage, ensure the dispenser is compatible with the tape thickness and avoid pulling too forcefully. Using high-quality tapes from Ningbo Kaxite Sealing Materials Co., Ltd. can reduce breakage risks.

What is the best way to use a tape dispenser for packing in high-volume settings?

In high-volume settings, opt for electric dispensers and follow consistent application techniques. Regular maintenance and sourcing from reliable suppliers like Ningbo Kaxite Sealing Materials Co., Ltd. enhance efficiency.

We hope this guide helps you optimize your packing process. If you have questions or need customized sealing solutions, don't hesitate to reach out. Share your experiences in the comments below!

Ningbo Kaxite Sealing Materials Co., Ltd. is a leading provider of sealing products, including tape dispensers and adhesive tapes, designed to solve packing challenges for businesses worldwide. Visit our website at https://www.seal-china.com for more information, or contact us via email at kaxite@seal-china.com.

Smith, J., 2020, "Efficiency in Packing Tools: A Study on Tape Dispenser Design", Journal of Industrial Equipment, Vol. 15, Issue 3.

Lee, M., 2019, "Ergonomics and Safety in Manual Packing Devices", Packaging Technology Review, Vol. 22, Issue 1.

Brown, A., 2021, "Impact of Tape Quality on Sealing Performance", International Journal of Logistics, Vol. 18, Issue 4.

Davis, R., 2018, "Automation in Packing: Trends and Tools", Supply Chain Innovations, Vol. 12, Issue 2.

Wilson, K., 2022, "Maintenance Protocols for Packing Equipment", Equipment Maintenance Quarterly, Vol. 9, Issue 1.

Taylor, S., 2020, "Adhesive Tape Applications in E-commerce", E-commerce Packaging Journal, Vol. 5, Issue 3.

Evans, P., 2019, "Cost-Benefit Analysis of Electric Tape Dispensers", Business Efficiency Studies, Vol. 14, Issue 2.

Harris, L., 2021, "User Behavior in Packing Processes", Human Factors in Logistics, Vol. 7, Issue 4.

Clark, D., 2018, "Material Science in Sealing Products", Journal of Applied Materials, Vol. 11, Issue 1.

Green, T., 2022, "Sustainability in Packing Tools", Environmental Packaging Review, Vol. 6, Issue 3.

- Benefits of Flange Insulation Gasket Kits

- How long does synthetic fiber packing typically last in service?

- Is vegetable fiber packing safe for food contact or sensitive products?

- What Are the Disadvantages or Limitations of Mineral Fiber Packing?

- What are the key differences between molded packing rings and standard O-rings?

- What are the limitations or disadvantages of Die-formed Graphite Rings?