Graphite Packing

What is Graphite Packing?

Graphite packing is a high-performance sealing material made from flexible graphite, designed to provide superior leak prevention in demanding industrial applications. It is manufactured through a process that compresses exfoliated graphite into tapes, coils, or rings, resulting in a material with exceptional thermal conductivity, chemical resistance, and self-lubricating properties. This makes it ideal for use in pumps, valves, flanges, and other equipment where high temperatures, aggressive chemicals, or dynamic movements are present. Unlike traditional packing materials, graphite packing maintains its integrity under extreme conditions, reducing downtime and maintenance costs.

Key Features and Benefits

- High-temperature resistance: Operates effectively from -200°C to 600°C in oxidizing atmospheres and up to 3000°C in non-oxidizing environments.

- Excellent chemical resistance: Resists most acids, alkalis, and solvents, ensuring longevity in corrosive applications.

- Self-lubricating: Reduces friction and wear on shafts and stems, extending equipment life.

- Thermal conductivity: Efficiently dissipates heat, preventing overheating in high-temperature systems.

- Flexibility and conformability: Easily adapts to irregular surfaces, providing a tight seal without requiring high compression forces.

- Low emission: Minimizes fugitive emissions, complying with environmental regulations.

Product Parameters and Specifications

Our graphite packing products are available in various forms, including braided, die-formed, and foil types, each tailored to specific operational needs. Below is a detailed table of standard parameters to help you select the right product for your application.

| Parameter | Value Range | Unit | Notes |

|---|---|---|---|

| Density | 1.0 - 1.3 | g/cm³ | Adjustable based on compression; higher density offers better sealing. |

| Temperature Range | -200 to 600 (oxidizing), up to 3000 (non-oxidizing) | °C | Non-oxidizing environments include inert gases or vacuum. |

| Thermal Conductivity | 50 - 150 | W/m·K | Superior to many packing materials, aiding heat dissipation. |

| pH Resistance | 0 - 14 | - | Resists strong acids and bases; exceptions include strong oxidizing agents. |

| Tensile Strength | 5 - 15 | MPa | Provides mechanical strength without brittleness. |

| Compression Set | < 20% | - | Low set ensures long-term sealing performance. |

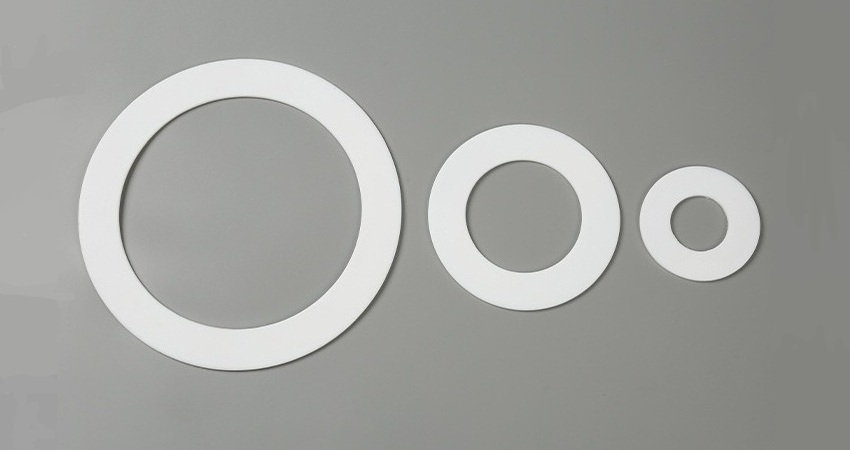

| Forms Available | Coil, tape, ring, braided | - | Custom sizes and shapes can be manufactured. |

Applications of Graphite Packing

Graphite packing is versatile and used across multiple industries due to its robust properties. Common applications include:

- Chemical processing: Seals in pumps and valves handling corrosive fluids.

- Power generation: Used in turbines, boilers, and heat exchangers for high-temperature sealing.

- Oil and gas: Prevents leaks in refineries and pipelines under high pressure and temperature.

- Pharmaceutical: Ensures sterile and leak-free operations in manufacturing equipment.

- Food and beverage: Safe for use in processing due to non-toxic nature and compliance with FDA standards.

- Automotive: Applied in exhaust systems and engines for thermal management.

Installation Guidelines

Proper installation is crucial for optimal performance of graphite packing. Follow these steps for best results:

- Clean the shaft or stem thoroughly to remove any old packing or debris.

- Measure and cut the packing to the required length, ensuring a clean, square cut.

- Wrap the packing around the shaft, staggering joints by at least 90 degrees for each ring.

- Insert the rings into the stuffing box, using a tamping tool to seat them gently without over-compressing.

- Tighten the gland evenly until slight resistance is felt, then operate the equipment to allow the packing to settle.

- After running, retighten the gland as necessary to achieve a leak-free seal, avoiding overtightening to prevent wear.

Frequently Asked Questions (FAQ)

What is the maximum temperature graphite packing can withstand?

Graphite packing can operate continuously up to 600°C in oxidizing atmospheres and up to 3000°C in non-oxidizing environments, such as inert gases or vacuum. This makes it suitable for extreme heat applications like furnaces or high-temperature reactors.

Is graphite packing resistant to chemicals?

Yes, graphite packing offers excellent resistance to a wide range of chemicals, including acids, alkalis, and organic solvents, within a pH range of 0-14. However, it should be avoided in strong oxidizing agents like nitric acid or perchloric acid, which can degrade the material.

How does graphite packing compare to asbestos or PTFE packing?

Graphite packing outperforms asbestos and PTFE in high-temperature applications and thermal conductivity. It is non-toxic unlike asbestos, and has better chemical resistance and lower friction than PTFE, reducing maintenance and improving safety in industrial settings.

Can graphite packing be used in food-grade applications?

Yes, pure graphite packing is FDA-compliant and suitable for food and beverage processing. It is non-toxic, odorless, and does not contaminate products, making it ideal for seals in mixers, pumps, and valves within the industry.

How often should graphite packing be replaced?

Replacement intervals depend on operating conditions, such as temperature, pressure, and media. Under normal conditions, graphite packing can last several years. Regular inspection for leaks or wear is recommended, and replacement should occur when leakage exceeds acceptable levels or during scheduled maintenance.

Does graphite packing require lubrication?

No, graphite packing is self-lubricating due to the layered structure of graphite, which reduces friction and wear on equipment. This eliminates the need for external lubricants, simplifying maintenance and reducing contamination risks.

What forms are available for graphite packing?

Graphite packing comes in various forms, including coils, tapes, rings, and braided styles. Custom shapes and sizes can be manufactured to fit specific equipment, ensuring optimal sealing performance for diverse applications.

Is graphite packing environmentally friendly?

Yes, graphite packing is eco-friendly as it produces minimal fugitive emissions and is made from natural graphite, which is abundant and recyclable. It helps industries comply with environmental regulations by reducing leakage and waste.

- View as

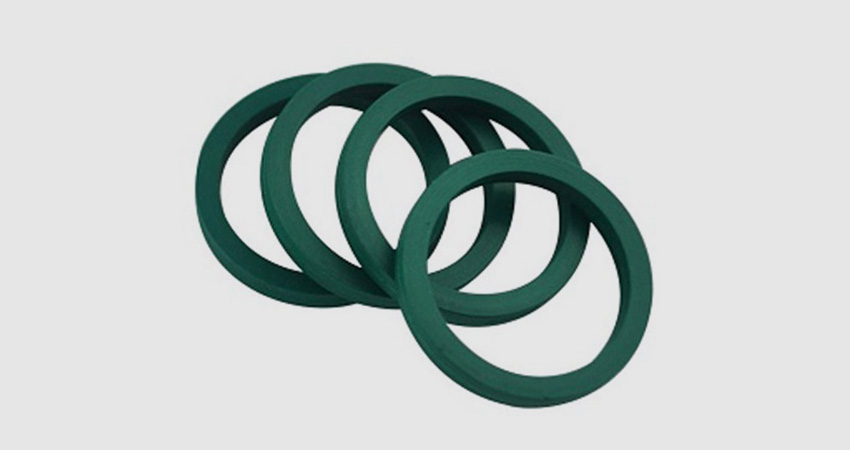

Graphite Packing Reinforced with Metal Wire