Ptfe Products

Understanding PTFE: The Miracle Material

Polytetrafluoroethylene, widely known as PTFE Products, is a high-performance fluoropolymer with exceptional properties that make it indispensable across various industries. Its unique molecular structure provides unparalleled chemical resistance, low friction, and thermal stability, earning it the nickname "Teflon" (a common brand name). From aerospace to medical devices, PTFE components ensure reliability and efficiency in demanding environments. This article delves into the specifications, applications, and FAQs surrounding PTFE products, offering a comprehensive guide for professionals and enthusiasts alike.

Key Properties of PTFE Products

PTFE boasts a range of characteristics that set it apart from other materials:

- Chemical Inertness: Resistant to almost all chemicals, including acids, bases, and solvents.

- Low Friction Coefficient: One of the slipperiest materials, reducing wear and energy loss.

- High Temperature Resistance: Operates effectively from -200°C to 260°C (-328°F to 500°F).

- Excellent Electrical Insulation: Non-conductive and stable in various electrical applications.

- Non-stick Surface: Ideal for coatings in cookware and industrial processes.

- Low Moisture Absorption: Minimal water uptake, maintaining integrity in humid conditions.

Detailed Product Parameters

Our PTFE products are manufactured to meet stringent standards, with parameters tailored for specific uses. Below is a table summarizing key specifications for common PTFE forms:

| Product Type | Density (g/cm³) | Tensile Strength (MPa) | Elongation at Break (%) | Max Operating Temp (°C) | Common Applications |

|---|---|---|---|---|---|

| Virgin PTFE Rods | 2.15 - 2.20 | 20 - 35 | 300 - 500 | 260 | Seals, bearings, insulators |

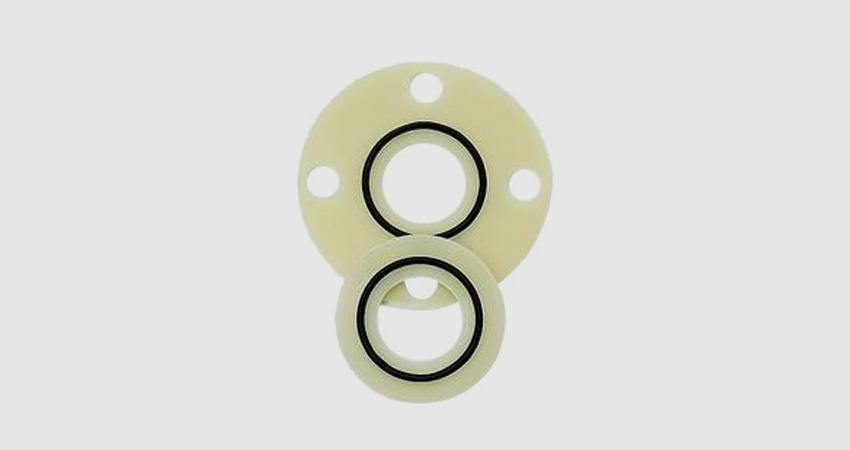

| PTFE Sheets | 2.10 - 2.30 | 15 - 30 | 200 - 400 | 260 | Gaskets, liners, lab equipment |

| PTFE Tubes | 2.15 - 2.25 | 10 - 25 | 250 - 450 | 260 | Fluid handling, electrical conduits |

| Filled PTFE (e.g., glass-filled) | 2.20 - 2.50 | 15 - 40 | 100 - 300 | 260 | High-wear parts, mechanical components |

Additional parameters include dielectric strength (≥20 kV/mm), coefficient of friction (0.05 - 0.10), and flammability rating (UL94 V-0). Custom formulations are available with fillers like carbon, graphite, or bronze to enhance properties such as wear resistance or conductivity.

Applications of PTFE Products

PTFE's versatility enables its use in numerous sectors:

- Industrial: Seals, valves, and pumps in chemical processing due to corrosion resistance.

- Electrical: Insulators and cable jacketing for high-voltage applications.

- Medical: Catheters and implants benefiting from biocompatibility and sterility.

- Automotive: Fuel system components and bearings reducing friction and wear.

- Consumer Goods: Non-stick coatings for cookware and bakeware.

Frequently Asked Questions (FAQ) About PTFE Products

What is PTFE, and how is it different from other plastics?

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer with a carbon-fluorine bond that grants it superior chemical resistance and thermal stability compared to conventional plastics like polyethylene or PVC. It does not melt under high heat but may soften, and it remains inert to most chemicals, making it unique for extreme environments.

Are PTFE products safe for food contact?

Yes, PTFE is FDA-approved for food contact applications. When used as a coating in cookware, it is non-toxic and does not react with food, provided it is not overheated beyond its recommended temperature range (typically below 260°C) to avoid decomposition.

Can PTFE be used in high-pressure applications?

PTFE has good compressive strength but may cold-flow under sustained high pressure. For high-pressure uses, filled PTFE variants (e.g., with glass or carbon) are recommended to improve creep resistance and maintain dimensional stability.

How do I clean and maintain PTFE products?

Clean PTFE with mild soap and water or solvents like isopropyl alcohol. Avoid abrasive materials that could scratch the surface. For non-stick coatings, use soft sponges to preserve the finish. Regular inspection for wear or damage is advised in industrial settings.

What are the environmental impacts of PTFE?

PTFE is inert and does not degrade easily, contributing to persistence in landfills if not recycled. However, it is recyclable through specialized processes. Manufacturing involves fluorochemicals, so proper disposal and recycling efforts are encouraged to minimize environmental footprint.

Can PTFE be machined or customized?

Yes, PTFE is easily machined using standard tools for cutting, drilling, or turning. It can be fabricated into custom shapes, sheets, rods, or tubes based on specifications. Fillers can be added to tailor properties like hardness or conductivity for specific needs.

Is PTFE suitable for outdoor applications?

PTFE performs well outdoors due to its UV resistance and low moisture absorption. It does not degrade easily from weathering, making it suitable for applications like architectural coatings or outdoor electrical insulation.

What is the lifespan of PTFE products?

Lifespan varies based on application; for example, non-stick coatings may last several years with proper care, while industrial seals might require replacement after 1-5 years depending on operating conditions like temperature, pressure, and chemical exposure.

- View as

40% Bronze Powder Filled Teflon PTFE Tube

25% Bronze Powder Filled Teflon PTFE Tube

Graphite Filled PTFE Tube

Bronze Powder Filled PTFE Tube

Carbon Fiber Filled PTFE Tube