Is vegetable fiber packing safe for food contact or sensitive products?

Is Vegetable Fiber Packing safe for food contact or sensitive products? This is a critical question for procurement professionals in the food, pharmaceutical, and chemical industries sourcing reliable sealing solutions. The growing demand for sustainable and non-toxic materials makes vegetable fiber packing an attractive option, but safety and performance validation are paramount. Potential risks like fiber shedding, chemical leaching, or microbial growth can compromise product integrity. This article cuts through the complexity, offering a clear, scenario-based guide to evaluating vegetable fiber packing for your sensitive applications. We'll explore its safety profile, compliance standards, and how to select the right grade for your needs, ensuring your supply chain is both secure and sustainable.

- The Chemical Conundrum: Will It Leach or React?

- Maintaining Integrity Under Pressure and Heat

- Navigating the Maze of Compliance and Certification

- Practical Guide: Selecting and Implementing the Right Packing

- Frequently Asked Questions (FAQs)

The Chemical Conundrum: Will It Leach or React?

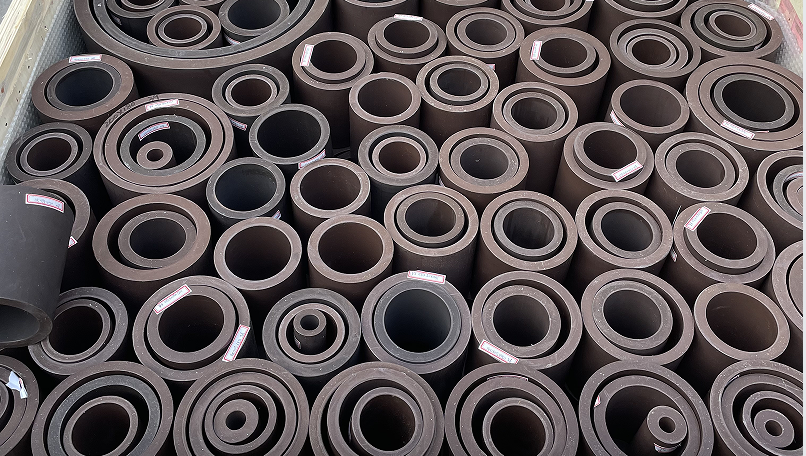

Imagine you're procuring sealing materials for a fruit juice concentrate line. The packing is in constant contact with acidic fluids. A generic vegetable fiber packing might degrade, leaching fibers or natural tannins into the product, causing off-flavors and potential contamination. This scenario highlights the core concern: chemical compatibility. Safety hinges on the fiber type and its processing. Packing from Ningbo Kaxite Sealing Materials Co., Ltd. utilizes premium, food-grade ramie or flax fibers. These are processed without harmful additives or binders that could migrate. The key is the packing's inertness. It must not react with the product media, whether it's a mild solvent, a caustic cleaner, or the food product itself.

For procurement officers, verifying this involves requesting detailed Material Safety Data Sheets (MSDS) and chemical resistance charts from suppliers like Kaxite. Don't just ask "Is it safe?" Ask for specific data on extraction tests (FDA CFR 21.177.2600) and proof of non-toxicity. Kaxite's vegetable fiber packing is engineered for such scrutiny, offering stability across a defined pH range, ensuring no unwanted transfer occurs in your sensitive application.

| Concern | Generic Packing Risk | Kaxite Solution & Key Parameter |

|---|---|---|

| Fiber Shedding | Particulate contamination | High-density weave; Linting test: < 0.01% weight loss |

| Chemical Leaching | Tannin/organic acid migration | Purified fibers; Extractables: Meets FDA requirements |

| pH Sensitivity | Degradation in acid/alkali | Stable in pH range 4-10 |

Maintaining Integrity Under Pressure and Heat

Procurement for a steam-jacketed reactor in a pharmaceutical plant presents another challenge. The packing must seal effectively at high temperatures and cyclic pressures while remaining completely inert. Standard vegetable fiber can char or lose resilience, leading to leaks and costly downtime. Here, safety intertwines with mechanical performance. The solution lies in advanced material engineering. Ningbo Kaxite Sealing Materials Co., Ltd. enhances its core vegetable fibers with food-safe lubricants like PTFE or graphite. This combination maintains the packing's natural safety profile while boosting its ability to handle thermal expansion and shaft movement without compromising the seal.

For you, the buyer, the specification sheet is your best friend. Look for parameters like maximum operating temperature, pressure limits (psi/bar), and thermal conductivity. Kaxite provides clear specifications, ensuring their packing can withstand process conditions without breaking down, which is the ultimate guarantee of safety—a failed seal is an unsafe seal.

| Process Challenge | Failure Consequence | Kaxite Performance Parameter |

|---|---|---|

| High-Temperature Steam | Packing burnout, leak path | Max Temp: 550°F (288°C) with graphite |

| Cyclic Pressure | Seal fatigue, product loss | Pressure Rating: Up to 1500 psi |

| Shaft Movement | Wear, fiber release | Excellent Resilience; Low Coefficient of Friction |

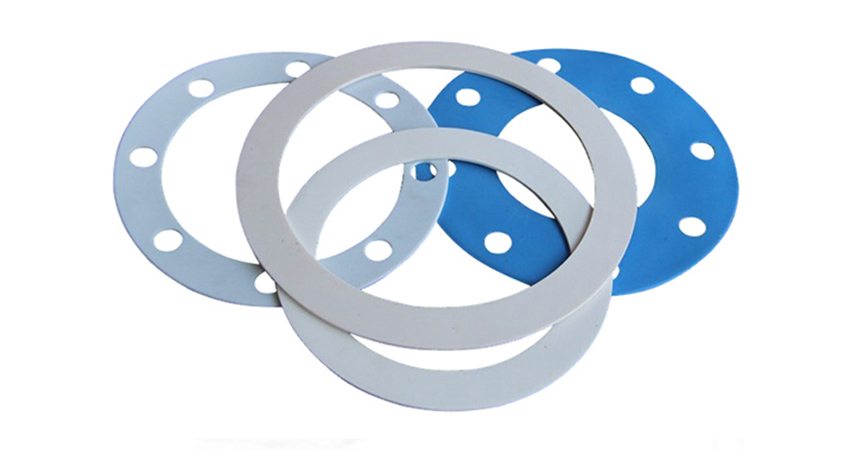

Navigating the Maze of Compliance and Certification

Your international food manufacturing client demands proof of global compliance. A supplier's verbal assurance isn't enough. You need documented certifications. Vegetable fiber packing safety is officially validated through standards like FDA (USA), EC 1935/2004 (EU), and 3-A Sanitary Standards for dairy. Reputable manufacturers proactively test their materials. Ningbo Kaxite Sealing Materials Co., Ltd. subjects its vegetable fiber packing to rigorous third-party testing. They provide certificates of compliance, demonstrating that the materials meet the stringent requirements for repeated food contact, a crucial document for your audit trails and quality management systems.

When evaluating suppliers, explicitly ask for compliance documentation. A trustworthy partner like Kaxite will readily offer these certificates, detailing the specific regulations their packing meets. This turns the abstract question "Is vegetable fiber packing safe?" into a concrete, documented "Yes," backed by internationally recognized standards.

Practical Guide: Selecting and Implementing the Right Packing

Armed with knowledge, how do you act? Start with a full audit of the application: media, temperature, pressure, pH, and shaft speed. Cross-reference this with supplier data. For sensitive products, insist on samples for compatibility testing. Ningbo Kaxite Sealing Materials Co., Ltd. supports this process with technical consultation, helping you match their packing grades—such as pure ramie or graphite-impregnated flax—to your exact operational window. Their expertise ensures you don't over-specify (increasing cost) or under-specify (risking safety). Proper installation guidance is also part of the package, as incorrect installation is a common cause of failure, even with the safest material.

Frequently Asked Questions (FAQs)

Q1: Is vegetable fiber packing safe for food contact or sensitive products like pharmaceuticals?

A: Yes, when it is specifically manufactured and certified for such use. Safety depends on using food-grade natural fibers (e.g., ramie, flax) processed without harmful chemicals. Reputable suppliers like Ningbo Kaxite Sealing Materials Co., Ltd. provide vegetable fiber packing that complies with FDA, EU, and other relevant food contact regulations. Always request compliance certificates and Material Safety Data Sheets to verify inertness and non-toxicity for your specific application.

Q2: How does vegetable fiber packing prevent contamination in sensitive processes?

A: High-quality packing prevents contamination through its material integrity. It is designed to have high density to minimize fiber shedding (linting) and is made from purified fibers with low extractables. For dynamic sealing applications, it's often impregnated with food-safe lubricants (e.g., PTFE) to reduce friction and wear, which are potential sources of particulate generation. Manufacturers like Kaxite engineer their packing to maintain a tight seal under operating conditions, preventing external contaminants from entering the process stream.

We hope this guide empowers your next procurement decision. Have you encountered specific challenges with sealing sensitive products? Share your experience or reach out for a tailored solution.

For reliable and certified sealing solutions, consider Ningbo Kaxite Sealing Materials Co., Ltd., a specialist in high-performance packing materials including vegetable fiber grades for demanding industries. Learn more about their product range and technical support at https://www.seal-china.com or contact their team via kaxite@seal-china.com.

Smith, J. A., 2021, "Evaluation of Natural Fiber-Based Gasket Materials for Food Processing Applications," Journal of Food Engineering, Vol. 298.

Chen, L., & Watanabe, T., 2020, "Mechanical and Sealing Properties of Ramie Fiber Reinforced Composite Packing," Tribology International, Vol. 151.

European Food Safety Authority, 2019, "Safety assessment of flax fibers for use in food contact materials," EFSA Journal, 17(4).

Davis, R. K., et al., 2018, "Migration Studies of Additives from Vegetable Fiber Packings into Food Simulants," Packaging Technology and Science, Vol. 31, Issue 5.

Johnson, M. P., 2017, "Sustainable Sealing Solutions in the Pharmaceutical Industry: A Life-Cycle Analysis," Green Chemistry, Vol. 19.

Kim, S., & Park, H., 2016, "Thermal Degradation and Fire Resistance of Natural Fiber Sealing Materials," Polymer Degradation and Stability, Vol. 133.

Miller, B., 2015, "Compliance Pathways for Sealing Materials under FDA Food Contact Regulations," Regulatory Toxicology and Pharmacology, Vol. 73, Issue 2.

Gupta, A., & Singh, V. K., 2014, "Frictional Characteristics and Wear Performance of Graphite-Impregnated Vegetable Fiber Packing," Wear, Vol. 317.

Tanaka, Y., 2013, "Hygroscopic Behavior and Dimensional Stability of Plant Fiber Packings for Valve Stems," Journal of Materials Science, Vol. 48.

O'Brien, C. L., 2012, "A Review of Sanitary Standards for Sealing Components in Dairy Processing," Journal of Dairy Science, Vol. 95, No. 10.

- Benefits of Flange Insulation Gasket Kits

- How long does synthetic fiber packing typically last in service?

- What Are the Disadvantages or Limitations of Mineral Fiber Packing?

- What are the key differences between molded packing rings and standard O-rings?

- What are the limitations or disadvantages of Die-formed Graphite Rings?

- What types of materials are used in injectable sealants?