Benefits of Flange Insulation Gasket Kits

Flange insulation gasket kits play a crucial role in maintaining the integrity and efficiency of piping systems across various industries. From preventing electrochemical corrosion to enhancing safety, these kits offer multiple benefits that can significantly improve the lifespan and performance of your infrastructure. In this article, we will delve into the advantages of using flange insulation gasket kits and why they are essential for your piping systems.

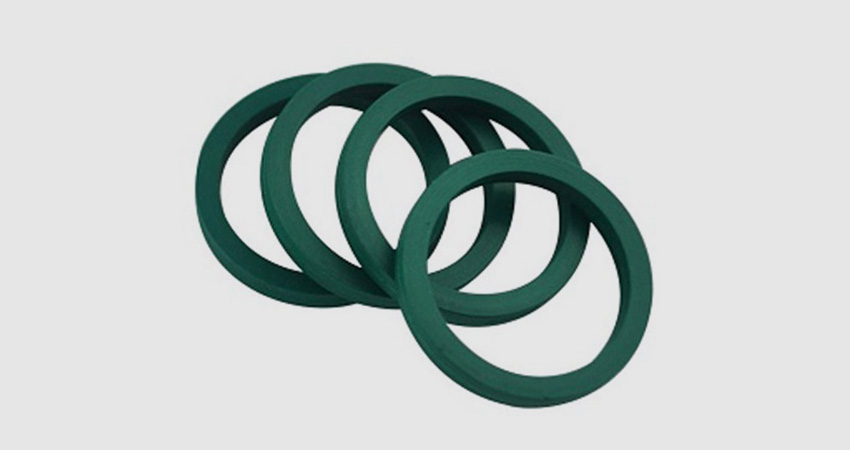

Understanding Flange Insulation Gasket Kits

Before exploring the benefits, it's important to understand what flange insulation gasket kits are. These kits are designed to prevent metal-to-metal contact between flanges, thus providing an insulating barrier. They typically include a gasket, insulating sleeves, and washers. This combination helps in breaking the electrical conductivity, which is vital in preventing corrosion and ensuring the safety of the piping system.

Key Benefits of Flange Insulation Gasket Kits

1. Prevention of Galvanic Corrosion

One of the primary advantages of using flange insulation kits is the prevention of galvanic corrosion. This type of corrosion occurs when two different metals come into contact in the presence of an electrolyte, causing one metal to corrode. By using insulation kits, you can effectively break the electrical path and prevent this type of corrosion, thereby prolonging the life of your piping system.

2. Enhanced Safety

Safety is a top priority in any industrial setting. Flange insulation gasket kits significantly enhance safety by reducing the risk of sparks. In environments where flammable gases or liquids are present, preventing sparks is crucial. The insulating properties of the gasket kits minimize the risk of sparking, thus maintaining a safer working environment.

3. Cost Savings

While the initial investment in flange insulation kits might seem significant, the long-term savings are substantial. By preventing corrosion and reducing maintenance needs, these kits can lead to significant cost savings over time. Reduced maintenance requirements mean less downtime and lower labor costs, which can have a positive impact on your bottom line.

4. Improved System Performance

Flange insulation kits contribute to the overall performance of piping systems by maintaining their integrity. By preventing leaks and ensuring that the system remains intact, these kits help in optimizing the flow of fluids and gases. This improved performance can lead to increased efficiency and reduced energy consumption, further enhancing cost-effectiveness.

Applications of Flange Insulation Gasket Kits

Flange insulation gasket kits are used across a wide range of industries, including oil and gas, petrochemical, water treatment, and more. Their versatility makes them suitable for various applications, ensuring that systems remain protected regardless of the environment.

1. Oil and Gas Industry

In the oil and gas industry, where pipelines are often exposed to harsh environmental conditions, flange insulation kits are vital. They help in preventing corrosion caused by seawater and other environmental factors, ensuring the longevity and reliability of the infrastructure.

2. Petrochemical Industry

The petrochemical industry deals with a variety of chemicals, many of which can be corrosive. Flange insulation kits help in protecting pipelines from the chemical reactions that can lead to corrosion, thereby ensuring that the systems remain efficient and safe.

3. Water Treatment Facilities

In water treatment facilities, maintaining the purity of the water is crucial. Flange insulation kits prevent the contamination that can occur due to corrosion, ensuring that the water remains clean and safe for consumption.

Choosing the Right Flange Insulation Gasket Kit

When selecting a flange insulation gasket kit, it's important to consider the specific needs of your application. Factors such as temperature, pressure, and the types of fluids or gases being transported should be taken into account to ensure that you choose the right kit for your needs.

Material Compatibility

Ensure that the materials used in the gasket kit are compatible with the substances being transported. This is crucial to prevent any chemical reactions that could compromise the integrity of the gasket.

Temperature and Pressure Ratings

Check the temperature and pressure ratings of the gasket kit to ensure that they are suitable for your application's operating conditions. Choosing a kit that can withstand the extremes of your system will ensure long-term reliability and performance.

Conclusion

Flange insulation gasket kits are an indispensable component in the maintenance and operation of piping systems. By preventing galvanic corrosion, enhancing safety, and reducing costs, these kits offer numerous benefits that can improve the performance and longevity of your infrastructure. Whether you are in the oil and gas industry, petrochemical sector, or water treatment facilities, investing in high-quality flange insulation kits is a smart decision that will pay off in the long run.

Incorporating flange insulation gasket kits into your maintenance strategy can lead to safer, more efficient, and cost-effective operations. With the right kit, you can ensure the integrity and reliability of your piping systems for years to come.

-

- How long does synthetic fiber packing typically last in service?

- Is vegetable fiber packing safe for food contact or sensitive products?

- What Are the Disadvantages or Limitations of Mineral Fiber Packing?

- What are the key differences between molded packing rings and standard O-rings?

- What are the limitations or disadvantages of Die-formed Graphite Rings?

- What types of materials are used in injectable sealants?