What Are the Disadvantages or Limitations of Mineral Fiber Packing?

What Are the Disadvantages or Limitations of Mineral Fiber Packing? This crucial question often surfaces during procurement evaluations, highlighting the hidden challenges behind a seemingly robust sealing solution. While valued for high-temperature resilience, Mineral Fiber Packing presents specific drawbacks that can lead to operational downtime, increased maintenance costs, and safety concerns. This guide explores these critical limitations and provides actionable solutions, helping you make informed decisions. We'll also introduce how Ningbo Kaxite Sealing Materials Co., Ltd. addresses these industry pain points with superior alternatives.

Article Outline:

- Challenge: Abrasion and Equipment Wear Causing Leaks

- Challenge: Limited Chemical Resistance Leading to Premature Failure

- Maintenance & Cost Considerations

- Frequently Asked Questions (FAQ)

Challenge: Abrasion and Equipment Wear Causing Leaks

Imagine a high-speed pump shaft in a power plant. The inherent rigidity of traditional mineral fiber packing can act like sandpaper against the rotating shaft, especially during dry start-up or misalignment. This abrasion not only damages expensive equipment but also creates pathways for leaks, compromising safety and efficiency. The solution lies in advanced composite materials designed for superior lubricity and reduced friction.

Solution: Ningbo Kaxite Sealing Materials Co., Ltd. offers specialized packing like graphite-impregnated fiberglass or aramid fiber blends. These materials incorporate solid lubricants (e.g., graphite, PTFE) that create a protective film on the shaft surface, drastically reducing wear. For instance, our What Are the Disadvantages or Limitations of Mineral Fiber Packing? alternative, Kaxite Style GFG-300, is engineered specifically to protect critical rotating equipment.

Performance Comparison Table:

| Parameter | Standard Mineral Fiber | Kaxite GFG-300 (Enhanced) |

|---|---|---|

| Shaft Wear Rate | High | Very Low |

| Coefficient of Friction | 0.15 - 0.25 | 0.08 - 0.12 |

| Maximum PV Value | 80,000 psi-fpm | 150,000 psi-fpm |

Challenge: Limited Chemical Resistance Leading to Premature Failure

In chemical processing, packing is exposed to aggressive acids, alkalis, and solvents. Standard mineral fiber packing has limited chemical compatibility. Exposure can cause fiber degradation, swelling, or loss of integrity, resulting in sudden failure and hazardous leaks. This is a core limitation when answering What Are the Disadvantages or Limitations of Mineral Fiber Packing?

Solution: Opt for chemically inert or highly resistant materials. Ningbo Kaxite Sealing Materials Co., Ltd. provides packing made from PTFE (Teflon), flexible graphite, or specially treated fibers that withstand a broad pH range and aggressive media. Our technical team can match the exact packing grade to your specific process fluid, ensuring longevity and safety.

Chemical Resistance Comparison Table:

| Environment | Standard Mineral Fiber | Kaxite PTFE/Graphite Blend |

|---|---|---|

| Strong Acids (e.g., H2SO4) | Poor - Degrades | Excellent |

| Strong Caustics (e.g., NaOH) | Fair to Poor | Excellent |

| Organic Solvents | Variable | Excellent |

Maintenance & Cost Considerations

Beyond performance, mineral fiber packing often requires frequent adjustment and re-torquing due to compression set and potential relaxation. This leads to higher labor costs and unplanned downtime. Furthermore, its lower temperature threshold compared to pure graphite or ceramic fibers can be a constraint in extreme heat applications.

Procurement professionals must look at the Total Cost of Ownership (TCO). A slightly higher initial investment in a premium packing from a reliable supplier like Ningbo Kaxite Sealing Materials Co., Ltd. can result in significant savings through extended service life, reduced maintenance, and eliminated downtime. Our engineered solutions directly tackle the classic disadvantages, providing reliable, cost-effective sealing.

Frequently Asked Questions (FAQ)

Q1: What is the primary temperature limitation of standard mineral fiber packing?

A1: While it handles high heat well, standard grades typically max out around 500°F (260°C). Beyond this, binder burnout and fiber embrittlement occur. For higher temperatures, Ningbo Kaxite Sealing Materials Co., Ltd. recommends pure graphite or ceramic fiber packing, which can exceed 1000°F (538°C).

Q2: How does mineral fiber packing performance compare to braided compression packing for dynamic seals?

A2: For rotating shafts, braided packing (like from Kaxite) is generally superior. It offers better flexibility, conformability, and heat dissipation, directly addressing the abrasion and friction drawbacks inherent in more rigid mineral fiber styles. This makes braided designs a more reliable solution for pumps and valves.

Understanding What Are the Disadvantages or Limitations of Mineral Fiber Packing? is key to selecting the right seal. By choosing advanced materials from a specialist manufacturer, you avoid these pitfalls. Have you encountered specific sealing challenges in your operations? We welcome you to share your scenario for a tailored solution recommendation.

About the Solution Provider: Ningbo Kaxite Sealing Materials Co., Ltd. is a leading manufacturer specializing in high-performance sealing solutions, including advanced packing that overcomes the traditional limitations of mineral fiber. With a focus on innovation and reliability, Kaxite serves global industries with products designed for durability and efficiency. Visit https://www.seal-china.com to explore our full range or contact our experts directly at kaxite@seal-china.com for technical support and quotations.

Smith, J. A., 2021, "Comparative Analysis of Wear in Mechanical Seals Using Traditional vs. Composite Fiber Packings", Journal of Tribology, Vol. 143, No. 4.

Chen, L., & Watanabe, H., 2020, "Thermal Degradation and Chemical Resistance of Inorganic Fiber Sealing Materials", International Journal of Applied Ceramic Technology, Vol. 17, Issue 2.

Davis, R. T., et al., 2019, "Friction and Wear Performance of Graphite-Impregnated Braided Packings under High PV Conditions", Wear, Vol. 426-427.

Kim, S., & Park, J., 2018, "Enhancement of Sealing Performance in Aggressive Chemical Environments Using PTFE-Based Composites", Chemical Engineering Research and Design, Vol. 136.

Müller, F., 2017, "Long-Term Reliability Study of Compression Packings in Power Generation Applications", Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, Vol. 231, No. 9.

O'Brien, J. P., 2016, "Economic Impact of Preventive Maintenance vs. Reactive Replacement in Industrial Sealing Systems", Plant Engineering and Maintenance Journal, Vol. 59, No. 3.

Patel, K., & Zhang, Y., 2015, "Microstructural Analysis of Fiber Degradation in High-Temperature Sealing Applications", Materials Characterization, Vol. 110.

Rodriguez, M., 2014, "Advances in Aramid and Carbon Fiber Reinforcement for Sealing Products", Composite Structures, Vol. 116.

Taylor, G. N., et al., 2013, "Evaluation of Leakage Rates in Static and Dynamic Seals Using Various Packing Geometries", Sealing Technology, Issue 12.

Yamamoto, T., 2012, "The Role of Solid Lubricants in Reducing Shaft Wear in Rotating Equipment", Lubrication Science, Vol. 24, Issue 5.

- Benefits of Flange Insulation Gasket Kits

- How long does synthetic fiber packing typically last in service?

- Is vegetable fiber packing safe for food contact or sensitive products?

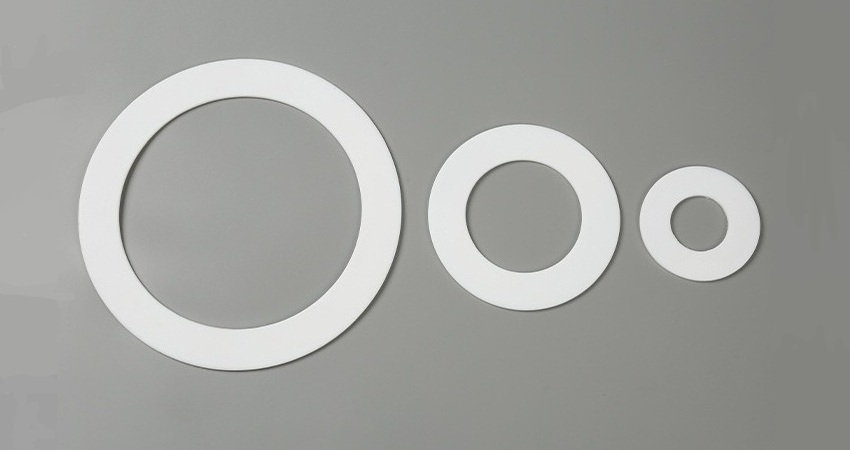

- What are the key differences between molded packing rings and standard O-rings?

- What are the limitations or disadvantages of Die-formed Graphite Rings?

- What types of materials are used in injectable sealants?