PTFE Rods

What Are PTFE Rods?

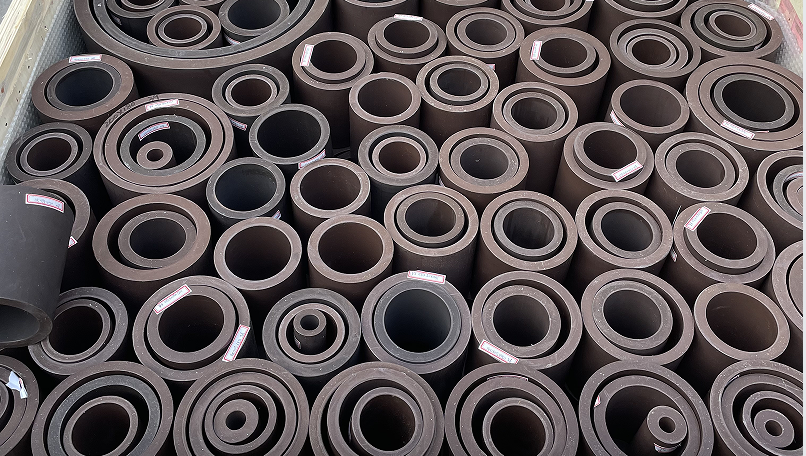

PTFE rods, made from polytetrafluoroethylene, are solid cylindrical forms known for their exceptional chemical resistance, low friction, and high-temperature stability. These rods are widely used in industrial applications where durability and non-reactivity are crucial. They serve as essential components in sectors like chemical processing, food and beverage, pharmaceuticals, and aerospace, providing reliable performance in demanding environments.

Key Features and Benefits

- Excellent chemical resistance to acids, bases, and solvents

- Low coefficient of friction, reducing wear and energy consumption

- High temperature tolerance, operating from -200°C to 260°C

- Non-stick properties, ideal for applications requiring easy release

- Electrical insulation capabilities

- UV and weather resistance for outdoor use

- FDA compliance for food contact applications

Product Specifications

Our PTFE rods are manufactured to meet strict quality standards, ensuring consistency and performance. Below is a detailed table of specifications based on common industry sizes and grades.

| Diameter (mm) | Length (mm) | Density (g/cm³) | Tensile Strength (MPa) | Elongation at Break (%) | Temperature Range (°C) |

|---|---|---|---|---|---|

| 10 | 1000 | 2.15 - 2.20 | 20 - 30 | 300 - 400 | -200 to 260 |

| 20 | 1000 | 2.15 - 2.20 | 20 - 30 | 300 - 400 | -200 to 260 |

| 30 | 1000 | 2.15 - 2.20 | 20 - 30 | 300 - 400 | -200 to 260 |

| 50 | 1000 | 2.15 - 2.20 | 20 - 30 | 300 - 400 | -200 to 260 |

| 100 | 500 | 2.15 - 2.20 | 20 - 30 | 300 - 400 | -200 to 260 |

Note: Custom sizes and grades are available upon request, including variations with fillers like glass or carbon for enhanced mechanical properties.

Applications of PTFE Rods

- Seals and gaskets in chemical pumps and valves

- Bearings and slides in machinery for reduced friction

- Insulators in electrical components

- Non-stick surfaces in food processing equipment

- Laboratory equipment due to chemical inertness

- Aerospace components for high-temperature environments

Frequently Asked Questions (FAQ)

What is the maximum temperature PTFE rods can withstand?

PTFE rods can continuously operate at temperatures up to 260°C (500°F) and briefly endure up to 300°C (572°F) without significant degradation. They also remain functional at cryogenic temperatures as low as -200°C (-328°F), making them suitable for extreme environments.

Are PTFE rods resistant to all chemicals?

PTFE rods exhibit excellent resistance to most chemicals, including strong acids, bases, and organic solvents. However, they can be affected by certain reactive metals like molten alkali metals and fluorine compounds at high temperatures. Always consult chemical compatibility charts for specific applications.

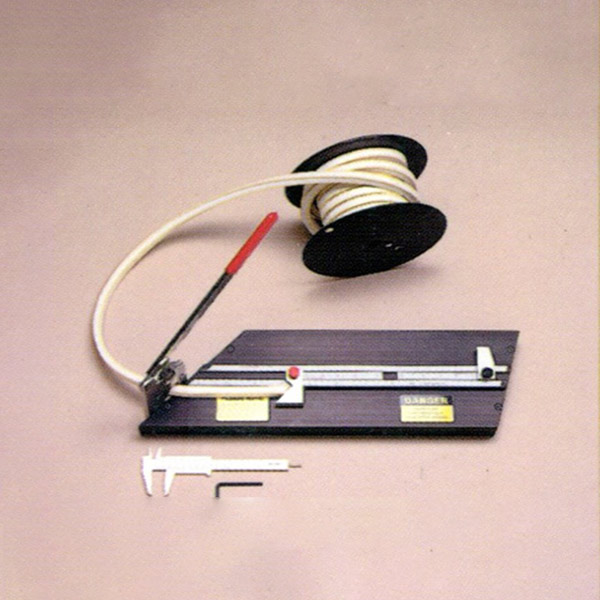

Can PTFE rods be machined easily?

Yes, PTFE rods are relatively soft and can be machined using standard tools like lathes, mills, and drills. They produce smooth finishes and require sharp tools to avoid deformation. It's recommended to use coolants to prevent overheating and maintain dimensional stability during machining.

What are the differences between virgin PTFE and filled PTFE rods?

Virgin PTFE rods are pure polytetrafluoroethylene, offering the best chemical resistance and electrical properties. Filled PTFE rods incorporate materials like glass fibers, carbon, or bronze to improve mechanical strength, wear resistance, or thermal conductivity, but may slightly reduce chemical resistance in some cases.

How do I choose the right diameter and length for my application?

Select the diameter based on the mechanical load and space constraints, and the length based on the part size or machining requirements. Common diameters range from 10mm to 100mm, with standard lengths of 500mm or 1000mm. For custom needs, provide detailed specifications to ensure optimal performance.

Are PTFE rods FDA approved for food contact?

Yes, virgin PTFE rods are generally FDA compliant and safe for food contact applications, as they are inert and non-toxic. However, filled PTFE rods might not be approved if the fillers are not food-grade, so verify the specific grade and filler type with the manufacturer.

How should PTFE rods be stored and handled?

Store PTFE rods in a cool, dry place away from direct sunlight and chemicals to prevent contamination or UV degradation. Handle with clean gloves to avoid oil or dirt transfer, which could affect performance in sensitive applications like food or pharmaceuticals.

What is the typical lead time for custom PTFE rod orders?

Lead times vary based on the order size and customization requirements. Standard sizes are often available from stock with shipping within a few days, while custom orders may take 2-4 weeks for manufacturing and quality checks. Contact suppliers for precise timelines.

Maintenance and Care Tips

- Clean with mild soap and water; avoid abrasive cleaners that could scratch the surface.

- Inspect regularly for signs of wear or deformation, especially in high-stress applications.

- Store horizontally on flat surfaces to prevent bending or warping over time.

- For filled PTFE rods, check compatibility with operating environments to avoid filler-related issues.

- View as

Glass Filled PTFE Rod