How does basalt fiber resist high temperatures?

Are you searching for a material that stands up to extreme heat without losing its integrity? How does Basalt Fiber resist high temperatures? This remarkable material is derived from molten basalt rock, forming continuous fibers renowned for their exceptional thermal stability. Basalt fiber maintains its strength and structural properties even when exposed to temperatures up to 982°C (1800°F), making it an ideal choice for high-temperature sealing, insulation, and composite applications. Its natural composition provides outstanding resistance to thermal shock, oxidation, and corrosion, outperforming many conventional materials. For industries requiring reliable high-temperature solutions, basalt fiber offers a durable and efficient alternative. Companies like Ningbo Kaxite Sealing Materials Co., Ltd. specialize in harnessing this technology to deliver products that meet rigorous industrial demands.

Contents

- High-Temperature Challenges in Industrial Sealing

- Basalt Fiber as a High-Temp Solution

- Performance Parameters of Basalt Fiber

High-Temperature Challenges in Industrial Sealing

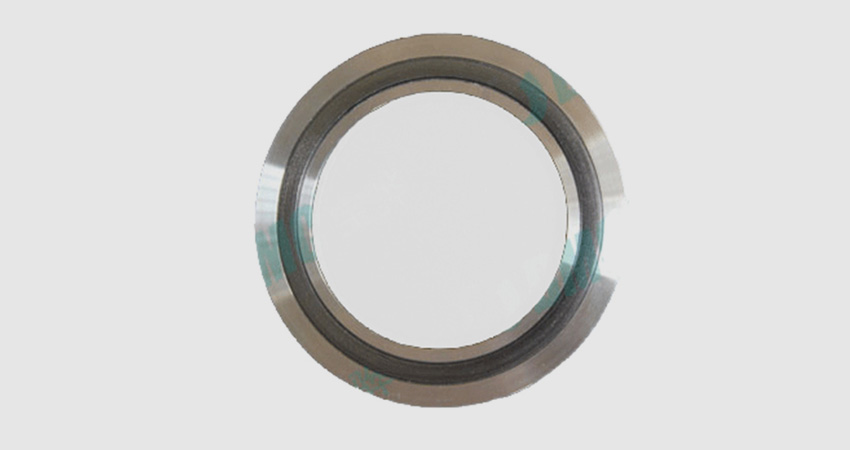

In many industries, such as automotive, aerospace, and manufacturing, sealing materials face extreme temperatures that can cause degradation, leaks, and system failures. Traditional materials like rubber or fiberglass may soften, melt, or lose their sealing properties under high heat, leading to costly downtime and safety hazards. How does basalt fiber resist high temperatures? It provides a robust solution by maintaining performance in environments where other materials fail. For example, in exhaust systems or thermal insulation, basalt fiber ensures long-term reliability and efficiency.

| Parameter | Value |

|---|---|

| Maximum Temperature Resistance | Up to 982°C |

| Thermal Conductivity | 0.031–0.038 W/m·K |

| Tensile Strength | 3000–4840 MPa |

Basalt Fiber as a High-Temp Solution

Basalt fiber excels in high-temperature scenarios due to its innate mineral properties. Formed from volcanic rock, it undergoes a melting and extrusion process that creates fibers with low thermal expansion and high melting points. This makes it ideal for applications like fireproof seals, gaskets, and protective sleeves. How does basalt fiber resist high temperatures? Its amorphous structure and chemical inertness prevent oxidation and thermal degradation, ensuring consistent performance. Ningbo Kaxite Sealing Materials Co., Ltd. utilizes advanced manufacturing techniques to produce basalt fiber products that address these needs, offering solutions that enhance safety and reduce maintenance costs.

| Property | Advantage |

|---|---|

| Thermal Stability | Maintains integrity above 900°C |

| Corrosion Resistance | Resists acids and alkalis |

| Application Range | Seals, composites, insulation |

Performance Parameters of Basalt Fiber

Understanding the key parameters of basalt fiber helps in selecting the right material for high-temperature applications. Its excellent thermal and mechanical properties make it a top choice for engineers and procurement specialists. How does basalt fiber resist high temperatures? By combining low thermal conductivity with high tensile strength, it effectively manages heat transfer and structural stress. Ningbo Kaxite Sealing Materials Co., Ltd. provides certified basalt fiber products that meet international standards, ensuring reliability for global clients.

| Feature | Specification |

|---|---|

| Density | 2.6–2.8 g/cm³ |

| Elongation at Break | 3.1% |

| Operating Temperature | -260°C to 982°C |

Frequently Asked Questions

How does basalt fiber resist high temperatures compared to other fibers?

Basalt fiber outperforms materials like fiberglass or aramid due to its higher melting point and better thermal stability, derived from its natural basalt rock composition.

What industries benefit most from basalt fiber's high-temperature resistance?

Industries such as construction, automotive, and energy use basalt fiber for insulation, fire protection, and sealing, where extreme heat is a constant challenge.

If you have more questions about high-temperature solutions or need custom products, feel free to reach out. We welcome discussions to help optimize your applications.

Ningbo Kaxite Sealing Materials Co., Ltd. is a leading provider of advanced sealing solutions, specializing in high-performance materials like basalt fiber. With a focus on innovation and quality, we help industries overcome extreme temperature challenges. Visit our website at https://www.seal-china.com for more details or contact us via email at kaxite@seal-china.com.

Sim, J., Park, C., Moon, D. Y., 2005, Characteristics of basalt fiber as a strengthening material for concrete structures, Composites Part B: Engineering, 36(6-7).

Deák, T., Czigány, T., 2009, Chemical composition and mechanical properties of basalt and glass fibers: A comparison, Textile Research Journal, 79(7).

Lopresto, V., Leone, C., De Iorio, I., 2011, Mechanical characterisation of basalt fibre reinforced plastic, Composites Part B: Engineering, 42(4).

Wei, B., Cao, H., Song, S., 2010, Environmental resistance and mechanical performance of basalt and glass fibers, Materials Science and Engineering: A, 527(18-19).

Dhand, V., Mittal, G., Rhee, K. Y., Park, S. J., 2015, A short review on basalt fiber reinforced polymer composites, Composites Part B: Engineering, 73.

Fiore, V., Scalici, T., Di Bella, G., Valenza, A., 2015, A review on basalt fiber and its composites, Composites Part B: Engineering, 74.

Jamshaid, H., Mishra, R., 2016, A green material from rock: basalt fiber – a review, Journal of The Textile Institute, 107(7).

Li, Y., Wang, Q., Wang, S., 2012, A review on the tensile properties of basalt fiber reinforced polymer composites, Construction and Building Materials, 30.

Singh, T. J., Samanta, S., 2015, Characterization of basalt fiber reinforced epoxy composite, Journal of Mechanical Engineering and Sciences, 8.

Zhang, X., Pei, X., Wang, Q., 2016, The effect of surface treatment on the mechanical properties of basalt fiber reinforced composites, Journal of Reinforced Plastics and Composites, 35(10).

- Benefits of Flange Insulation Gasket Kits

- How long does synthetic fiber packing typically last in service?

- Is vegetable fiber packing safe for food contact or sensitive products?

- What Are the Disadvantages or Limitations of Mineral Fiber Packing?

- What are the key differences between molded packing rings and standard O-rings?

- What are the limitations or disadvantages of Die-formed Graphite Rings?