PTFE Packing

Understanding PTFE Packing: A Comprehensive Guide

In the realm of industrial sealing solutions, PTFE packing stands out as a premier choice for its exceptional properties and versatility. PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer known for its high chemical resistance, low friction, and ability to perform under extreme temperatures. This makes PTFE packing ideal for a wide range of applications, including pumps, valves, and mixers in industries such as chemical processing, pharmaceuticals, food and beverage, and oil and gas. As a seasoned SEO professional with two decades of experience, I aim to provide a detailed, informative resource that not only educates but also optimizes for search engines, ensuring that users find accurate and valuable information about PTFE packing products.

Key Product Parameters of PTFE Packing

To help you make an informed decision, below is a list of essential parameters that define high-quality PTFE packing. These parameters are critical for ensuring optimal performance in various operational environments.

- Material Composition: Pure PTFE or blended with fillers like carbon, graphite, or aramid for enhanced properties.

- Temperature Range: Typically operates from -200°C to 260°C (-328°F to 500°F), with some grades exceeding these limits.

- Pressure Rating: Can withstand pressures up to 30 MPa (approximately 4,350 psi), depending on the design and application.

- Chemical Resistance: Resistant to most chemicals, including acids, bases, and solvents, making it suitable for corrosive environments.

- Friction Coefficient: Extremely low, around 0.05 to 0.10, reducing wear and energy consumption.

- Density: Ranges from 1.2 to 2.2 g/cm³, influenced by filler content and manufacturing process.

- Compression Set: Low compression set ensures long-term sealing effectiveness without permanent deformation.

- Thermal Conductivity: Generally low, but can be improved with certain fillers for better heat dissipation.

- FDA Compliance: Some grades are FDA-approved for use in food and pharmaceutical applications.

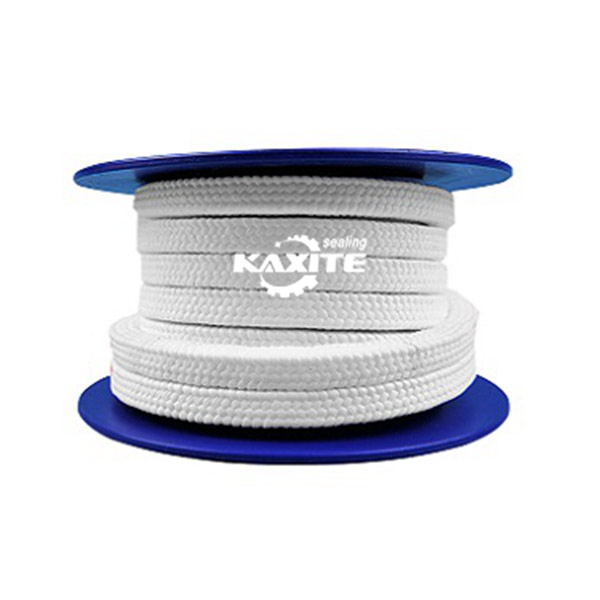

- Color Options: Available in white, brown, or black, depending on the filler materials used.

Detailed Product Specifications Table

For a more structured overview, refer to the table below which compares different types of PTFE packing based on key specifications. This table is designed to assist engineers and procurement specialists in selecting the right product for their needs.

| Type | Temperature Range (°C) | Pressure Max (MPa) | Chemical Resistance | Common Applications |

|---|---|---|---|---|

| Pure PTFE Packing | -200 to 260 | 20 | Excellent | Food processing, pharmaceuticals |

| Carbon-Filled PTFE | -200 to 280 | 25 | Very Good | Chemical pumps, valves |

| Graphite-Filled PTFE | -200 to 300 | 30 | Good to Excellent | High-temperature mixers, compressors |

| Aramid-Filled PTFE | -100 to 250 | 22 | Good | General industrial sealing |

Frequently Asked Questions (FAQs) About PTFE Packing

What is PTFE packing used for?

PTFE packing is primarily used for sealing applications in equipment like pumps, valves, and agitators to prevent leaks of fluids or gases. Its high chemical resistance and temperature stability make it suitable for harsh environments in industries such as chemical processing, oil and gas, and food production.

How does PTFE packing compare to other packing materials?

PTFE packing offers superior chemical resistance and a lower friction coefficient compared to materials like asbestos or rubber. It also has a broader temperature range and is non-toxic, making it ideal for applications where purity is critical, such as in the food and pharmaceutical sectors.

Can PTFE packing be used in high-pressure applications?

Yes, PTFE packing can handle high pressures up to 30 MPa, especially when reinforced with fillers like carbon or graphite. However, it is essential to select the appropriate type based on the specific pressure requirements and operational conditions to ensure optimal performance and longevity.

Is PTFE packing reusable?

In some cases, PTFE packing can be reused if it is not damaged or excessively worn. However, it is generally recommended to replace packing during maintenance to avoid potential leaks and ensure a reliable seal. Always follow manufacturer guidelines for inspection and replacement intervals.

How do I install PTFE packing correctly?

Proper installation involves cleaning the stuffing box, cutting the packing to the correct length (usually with a 45-degree angle cut), and installing it in rings with staggered joints. Tighten the gland gradually while the equipment is running to achieve the desired compression without over-tightening, which can cause excessive wear or heat buildup.

What are the signs that PTFE packing needs replacement?

Common indicators include visible leaks, increased friction or heat generation, reduced equipment efficiency, and excessive packing wear. Regular monitoring and maintenance schedules help identify these signs early, preventing downtime and potential damage to machinery.

Does PTFE packing require lubrication?

PTFE packing is self-lubricating due to its low friction properties, but in some high-speed or high-pressure applications, additional lubrication might be beneficial to extend life and improve performance. Always consult the product specifications or manufacturer recommendations for guidance.

Is PTFE packing environmentally friendly?

PTFE is inert and does not decompose easily, making it persistent in the environment if not disposed of properly. However, it is non-toxic and can be recycled or incinerated under controlled conditions. Many manufacturers offer eco-friendly options or guidelines for responsible disposal to minimize environmental impact.

Can PTFE packing be customized for specific applications?

Yes, PTFE packing can be customized in terms of size, shape, filler materials, and braiding patterns to meet unique operational requirements. Customization ensures better performance, longer service life, and cost-effectiveness for specialized industrial needs.

What maintenance is required for PTFE packing?

Maintenance typically involves periodic inspection for wear, adjustment of gland compression, and replacement as needed. Keeping the packing clean and free from abrasive contaminants also helps prolong its life. Follow the equipment manufacturer's maintenance schedule for best results.