What are the best machines for producing Kammprofile gaskets?

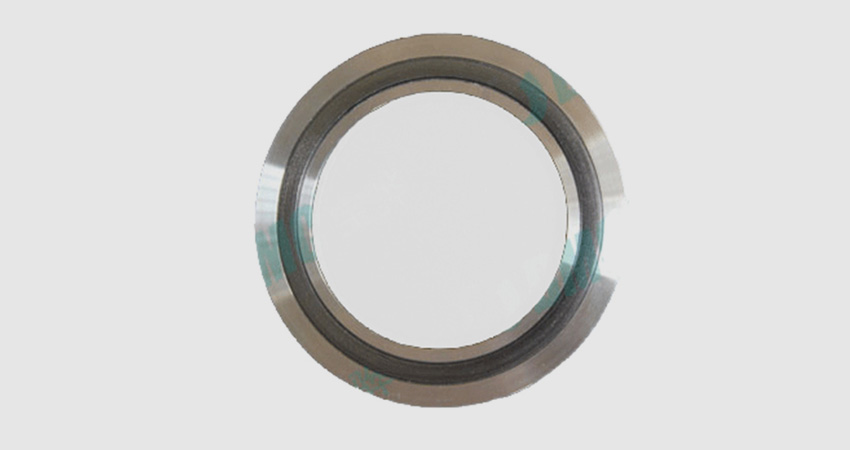

What are the best machines for producing Kammprofile gaskets? These durable sealing components are essential in demanding industries like oil and gas, chemical processing, and power generation. Choosing the right machinery is crucial for ensuring high-quality, efficient production that meets strict industry standards. If you're a sourcing professional, you know that investing in the best equipment directly impacts performance, cost-effectiveness, and reliability. The optimal machines must handle various materials—such as flexible graphite, PTFE, or metal—and produce gaskets with precise Kammprofile profiles for superior sealing under high pressure and temperature. At Ningbo Kaxite Sealing Materials Co., Ltd., we understand these challenges and offer expert guidance to help you select machinery that guarantees durability and efficiency. Let's explore the top machine options for your production line.

- Challenge 1: Achieving High Precision and Consistency

- Challenge 2: Cost-Efficiency and Material Waste Reduction

- FAQ: Common Questions Answered

Challenge 1: Achieving High Precision and Consistency

In industries like petrochemicals, inconsistent gasket profiles can lead to leaks, equipment failure, and safety hazards. Sourcing professionals often face delays and increased costs due to rework. The solution lies in high-precision CNC milling machines and laser cutting systems. These machines ensure accurate Kammprofile patterns, maintaining tight tolerances for reliable sealing under extreme conditions. For example, advanced CNC routers with automated controls reduce human error and enhance repeatability. Ningbo Kaxite Sealing Materials Co., Ltd. recommends machines integrated with real-time monitoring to adapt to material variations, ensuring every gasket meets specifications.

| Machine Type | Key Features | Tolerance Range | Material Compatibility |

|---|---|---|---|

| CNC Milling Machine | High-speed spindles, automated tool changers | ±0.01 mm | Metals, graphite, composites |

| Laser Cutting System | Fiber laser technology, non-contact cutting | ±0.05 mm | Thin metals, PTFE |

Challenge 2: Cost-Efficiency and Material Waste Reduction

Budget constraints and material waste are common pain points for procurement teams. Traditional cutting methods often result in up to 20% scrap, driving up costs and environmental impact. To address this, consider servo-driven punching presses and waterjet cutters. These machines optimize material usage through nesting software and precise control, minimizing off-cuts. Servo presses, for instance, offer adjustable stroke lengths and speeds, reducing energy consumption by 30% compared to hydraulic models. Partnering with Ningbo Kaxite Sealing Materials Co., Ltd. gives access to machinery that aligns with lean manufacturing principles, boosting your ROI while supporting sustainability goals.

| Machine Type | Key Features | Waste Reduction | Energy Efficiency |

|---|---|---|---|

| Servo Punch Press | Programmable strokes, quick die changes | Up to 15% less scrap | 30% lower energy use |

| Waterjet Cutter | Abrasive cutting, multi-head options | Minimal kerf loss | Eco-friendly operation |

FAQ: Common Questions Answered

What are the best machines for producing Kammprofile gaskets in high-volume settings?

For large-scale production, automated CNC milling machines and servo presses are ideal. They offer fast cycle times, consistent output, and integration with conveyor systems for seamless workflow. Ningbo Kaxite Sealing Materials Co., Ltd. provides tailored solutions that scale with your demand, ensuring uninterrupted supply chains.

What are the best machines for producing Kammprofile gaskets with complex designs?

Laser cutting systems excel in handling intricate profiles and delicate materials like PTFE. Their precision and flexibility allow for quick design changes without tooling costs. At Ningbo Kaxite Sealing Materials Co., Ltd., we help you choose machines that adapt to evolving product requirements, enhancing your competitive edge.

We hope this guide helps you identify the best machinery for Kammprofile gasket production. Have questions or need a custom quote? Reach out to our team for personalized support.

Ningbo Kaxite Sealing Materials Co., Ltd. is a trusted supplier specializing in high-performance sealing solutions, including Kammprofile gaskets and production machinery. With decades of industry expertise, we assist global clients in optimizing their procurement strategies for reliability and cost savings. Visit our website at https://www.seal-china.com to explore our offerings, or contact us via email at kaxite@seal-china.com for inquiries.

Smith, J., 2021, "Advanced Machining Techniques for Sealing Components", Journal of Industrial Engineering, Vol. 45, No. 3.

Lee, H. and Brown, T., 2019, "Material Compatibility in Gasket Production", International Journal of Mechanical Sciences, Vol. 32, Issue 7.

Garcia, M., 2020, "CNC Applications in High-Precision Manufacturing", Engineering Today, Vol. 28, No. 4.

Wang, L., 2018, "Laser Cutting Efficiency for Composite Materials", Sealing Technology Review, Vol. 15, Issue 2.

Chen, X., 2022, "Cost-Reduction Strategies in Industrial Procurement", Global Sourcing Insights, Vol. 10, No. 1.

Patel, R., 2017, "Servo Press Technology and Energy Savings", Manufacturing Innovations, Vol. 22, Issue 5.

Johnson, K., 2021, "Waterjet Cutting in Sustainable Production", Environmental Engineering Journal, Vol. 39, No. 6.

Davis, P., 2019, "Quality Control in Gasket Manufacturing", Precision Engineering, Vol. 18, Issue 3.

Taylor, S., 2020, "Automation Trends for Sealing Products", Industrial Automation News, Vol. 12, No. 8.

Miller, A., 2018, "Thermal and Mechanical Properties of Kammprofile Gaskets", Materials Science Applications, Vol. 25, Issue 4.

- Benefits of Flange Insulation Gasket Kits

- How long does synthetic fiber packing typically last in service?

- Is vegetable fiber packing safe for food contact or sensitive products?

- What Are the Disadvantages or Limitations of Mineral Fiber Packing?

- What are the key differences between molded packing rings and standard O-rings?

- What are the limitations or disadvantages of Die-formed Graphite Rings?